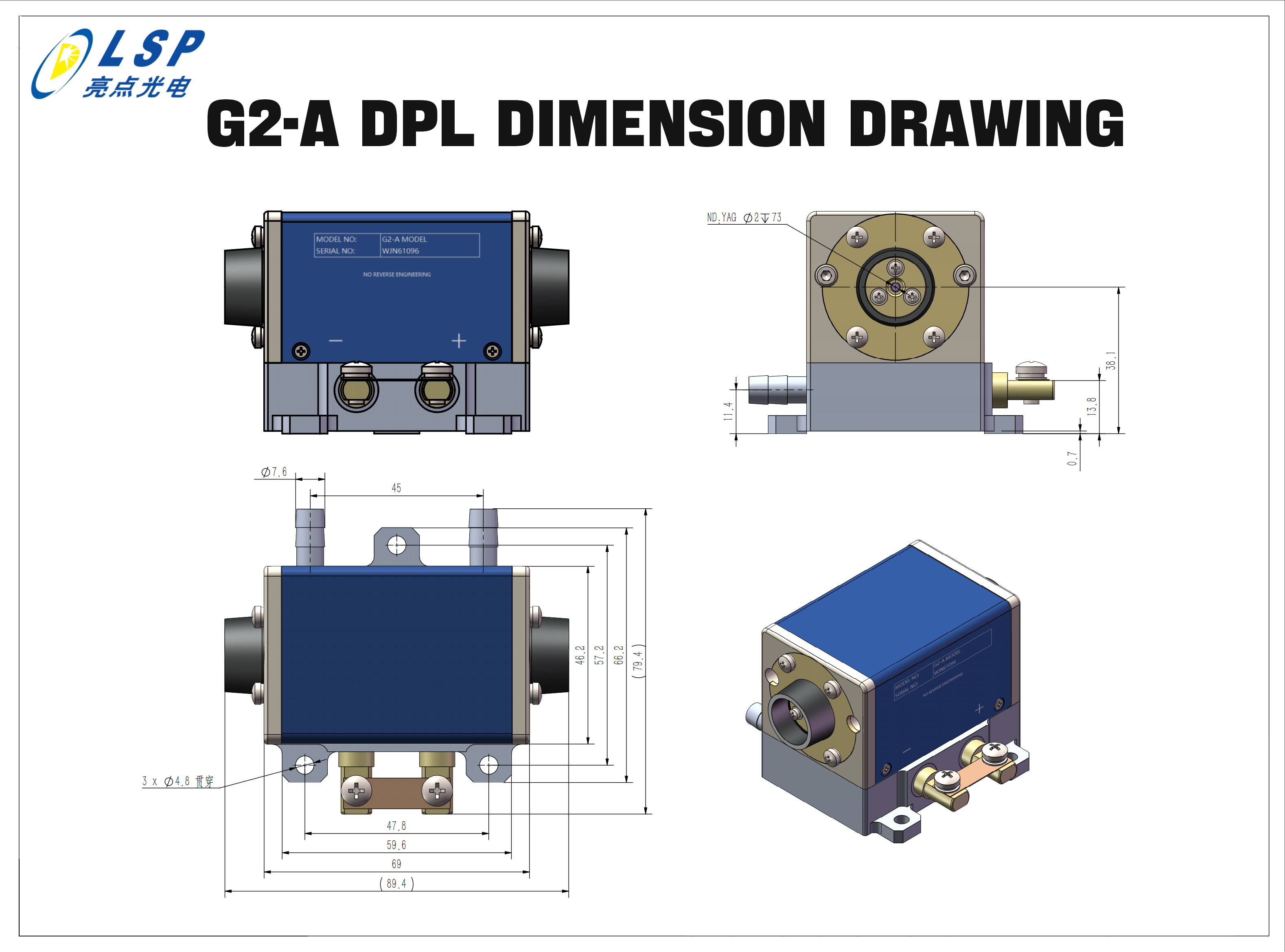

| Encapsulation Solder ye Diode Laser Bar Stacks | AuSn Packed |

| Central Wavelength | 1064nm |

| Output Power | ≥55W |

| Kushanda Current | ≤30 A |

| Kushanda Voltage | ≤24V |

| Working Mode | CW |

| Cavity Length | 900mm |

| Output Mirror | T = 20% |

| Kupisa Kwemvura | 25±3℃ |

Nyorera kune Yedu Social Media For Prompt Post

Iko kudiwa kweCW (Continuous Wave) diode-pumped laser modules iri kuwedzera nekukurumidza seyakakosha yekupomba sosi yeakasimba-nyika lasers.Aya ma module anopa akasiyana mabhenefiti kuti asangane nezvinodiwa zveyakasimba-state laser application.G2 - A Diode Pump Solid State Laser, chigadzirwa chitsva cheCW Diode Pump Series kubva kuLumiSpot Tech, ine nzvimbo yakakura yekushandisa uye kugona kuita zvirinani.

Muchinyorwa chino, Isu ticha sanganisira zvirimo zvinotarisa pane chigadzirwa mashandisirwo, zvigadzirwa zvemhando, uye zvakanakira chigadzirwa zvine chekuita neCW diode pombi solid-state laser.Pakupera kwechinyorwa, ini ndicharatidza bvunzo mushumo weCW DPL kubva kuLumispot Tech uye zvedu zvakakosha zvakanakira.

Nzvimbo Yekushandisa

High-simba semiconductor lasers anonyanya kushandiswa sepombi masosi kune akasimba-nyika lasers.Mumashandisirwo anoshanda, semiconductor laser diode-pombi sosi yakakosha pakugadzirisa iyo laser diode-pumped solid-state laser tekinoroji.

Iyi mhando yelaser inoshandisa semiconductor laser ine yakagadziriswa wavelength kubuda pachinzvimbo cheyakajairika Krypton kana Xenon Lamp kupomba makristasi.Nekuda kweizvozvo, iyi laser yakakwidziridzwa inonzi iyo 2ndchizvarwa cheCW pombi laser (G2-A), iyo ine hunhu hwekushanda kwepamusoro, hupenyu hurefu hwebasa, kunaka kwedanda remhando, kugadzikana kwakanaka, compactness uye miniaturization.

High-Simba Kupomba Mano

CW Diode Pump Source inopa yakanyanya kuputika kweyero yesimba remagetsi, ichipomba zvinobudirira iyo yepakati mune yakasimba-state laser, kuona kuita kwakanyanya kweiyo solid-state laser.Zvakare, simba rayo repamusoro-soro (kana simba repakati) rinogonesa huwandu hwakawanda hwekushandisa mukatiindasitiri, mishonga, uye sainzi.

Yakanakisa Beam uye kugadzikana

CW semiconductor kupomba laser module ine yakasarudzika mhando yemwenje wemwenje, nekugadzikana kwega, izvo zvakakosha kuti uzive inodzoreka chaiyo laser mwenje kubuda.Iwo ma modules akagadzirirwa kuburitsa yakanyatsotsanangurwa uye yakagadzikana danda profiles, kuve nechokwadi chekuvimbika uye kunoenderana kupomba kweiyo solid-state laser.Ichi chimiro chinosangana zvakakwana nezvinodiwa zvelaser application muindasitiri yekugadzira zvinhu, laser cutting, uye R&D.

Kuenderera mberi Wave Operation

Iyo CW inoshanda modhi inosanganisa zvese zvakanaka zvekuenderera mberi wavelength laser uye Pulsed Laser.Musiyano mukuru pakati peCW Laser uye Pulsed laser ndiko kubuda kwemagetsi.CW laser, iyo inozivikanwawo seContinuous wave laser, ine hunhu hweiyo yakagadzikana yekushanda modhi uye kugona kutumira inoenderera wave wave.

Compact uye Yakavimbika Dhizaini

CW DPL inogona kubatanidzwa nyore nyore mune yazvinoyakasimba-state laserzvichienderana ne compact dhizaini uye chimiro.Kuvaka kwavo kwakasimba uye zvikamu zvemhando yepamusoro zvinovimbisa kuvimbika kwenguva refu, kuderedza nguva yekudzikira uye mari yekugadzirisa, iyo inonyanya kukosha mukugadzira maindasitiri uye nzira dzekurapa.

Iko Kudiwa Kwemusika kweiyo Series yeDPL - Kukura Kwemusika Mikana

Sezvo kudiwa kwema-solid-state lasers kuri kuramba kuchiwedzera mumaindasitiri akasiyana, ndozvinoitawo kudiwa kwepamusoro-kushanda kwekupomba masosi seCW diode-pumped laser modules.Maindasitiri akaita sekugadzira, hutano, kudzivirira, uye tsvakiridzo yesainzi inotsamira pane yakasimba-nyika lasers yechokwadi maapplication.

Kupfupisa, seyo diode yekupomba sosi yeyakasimba-state laser, hunhu hwezvigadzirwa: yakakwirira-simba kupomba kugona, CW maitiro ekushanda, yakanakisa danda kunaka uye kugadzikana, uye compact-yakaumbwa dhizaini, inowedzera kudiwa kwemusika mune izvi. laser modules.Semupi, Lumispot Tech inoisawo simba rakawanda mukugadzirisa mashandiro uye matekinoroji anoshandiswa muDPL akatevedzana.

Chigadzirwa Bundle Seti yeG2-A DPL Kubva kuLumispot Tech

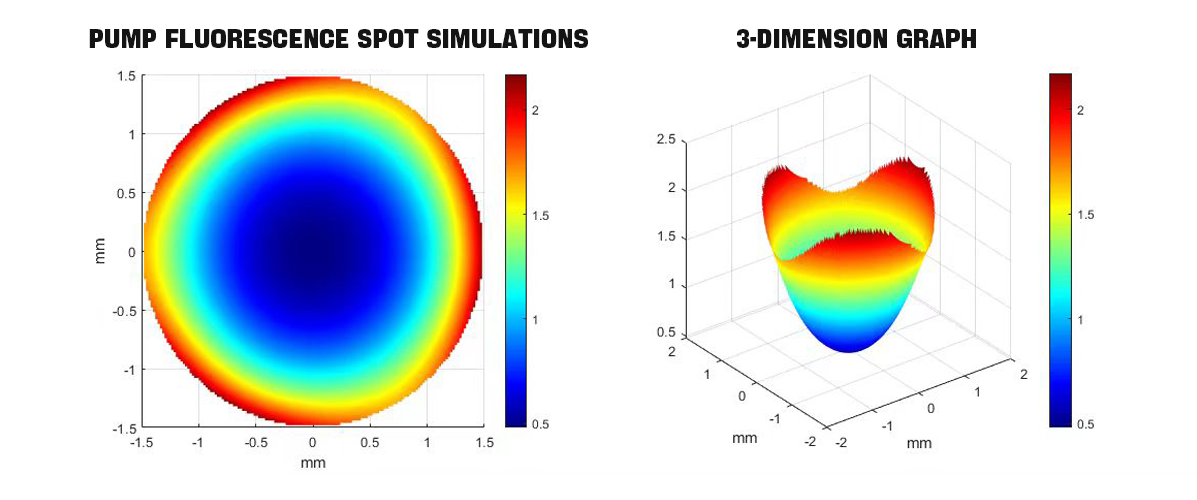

Seti yega yega yezvigadzirwa ine mapoka matatu emamodule akaturikidzana akaturikidzana, rimwe nerimwe boka reHorizontal Stacked Array modules kupomba simba ringangoita 100W@25A, uye simba rekupomba rakazara re300W@25A.

Iyo G2-A pombi fluorescence nzvimbo inoratidzwa pazasi:

Iyo Main Technical Data yeG2-A Diode Pump Solid State Laser:

Kusimba Kwedu MuTechnologies

1. Transient Thermal Management Technology

Semiconductor-pumped solid-state lasers anoshandiswa zvakanyanya kune quasi-inoenderera mberi wave (CW) application ine yakakwirira peak simba kubuda uye inoenderera mberi wave (CW) zvikumbiro zvine avhareji yemagetsi kubuda.Mune idzi lasers, kureba kwedhishi yekupisa uye chinhambwe chiri pakati pemachipisi (kureva, ukobvu hwe substrate uye chip) zvinokanganisa zvakanyanya kugona kwekupisa kwechigadzirwa.Iyo yakakura chip-to-chip chinhambwe inokonzeresa mukupisa kurinani asi inowedzera huwandu hwechigadzirwa.Sezvineiwo, kana chip spacing ikaderedzwa, saizi yechigadzirwa ichaderedzwa, asi chigadzirwa chekupisa kupisa kugona kunogona kunge kusina kukwana.Kushandisa iyo yakanyanya compact vhoriyamu kugadzira iyo yakakwana semiconductor-pumped solid-state laser inosangana nezvinodiwa zvekupisa kupisa ibasa rakaoma mukugadzira.

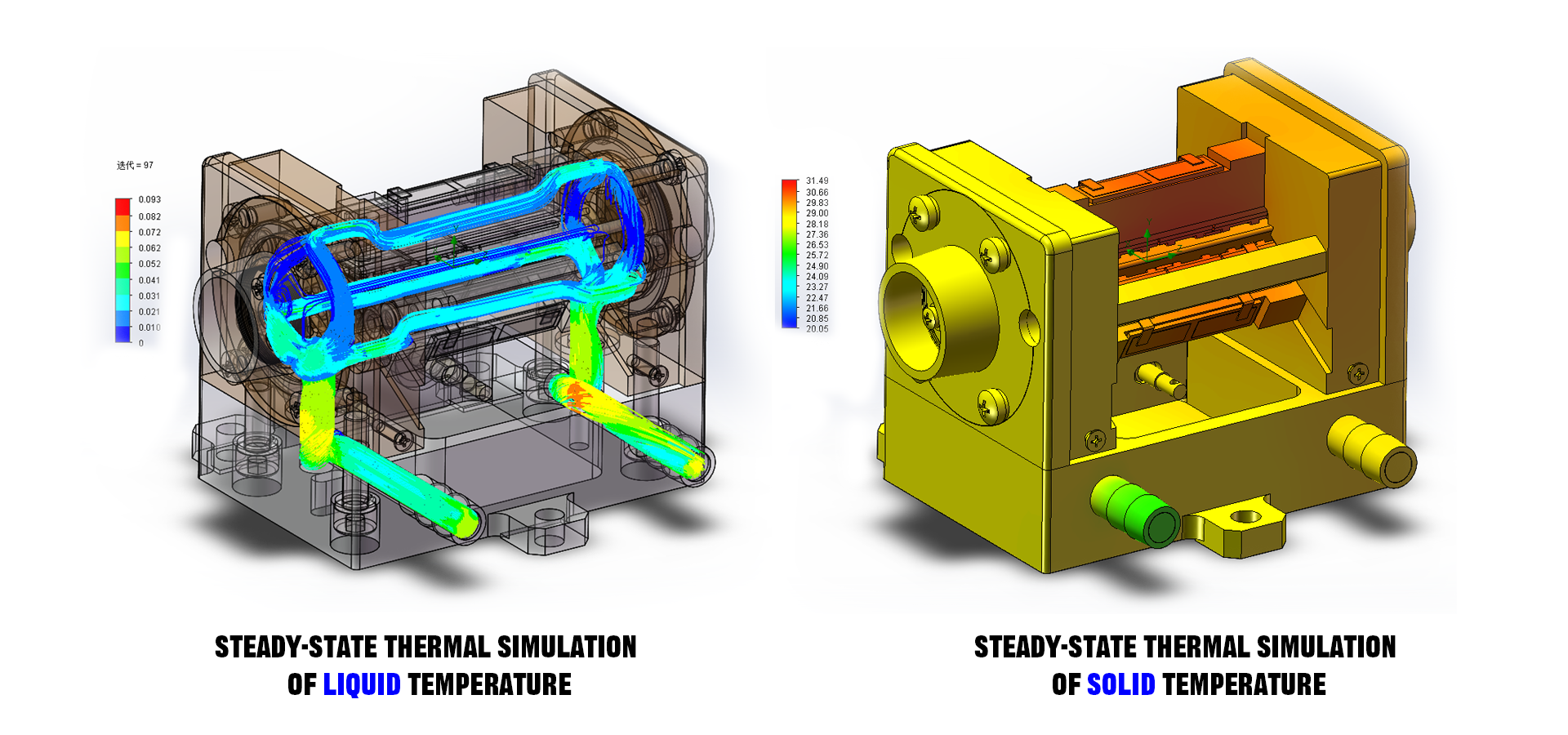

Girafu yeThe Steady-state Thermal Simulation

Lumispot Tech inoshandisa iyo inopera element nzira kutevedzera uye kuverenga tembiricha yenzvimbo yechishandiso.Musanganiswa wekutemesa kupisa kwakasimba kwakatsiga-mamiriro ekupisa kuenzanisira uye tembiricha yemvura tembiricha yekupisa kuenzanisira kunoshandiswa pakupisa kutevedzera.Kuenderera mberi nemamiriro ekushanda, sekuratidzwa pamufananidzo uri pazasi: chigadzirwa chinokurudzirwa kuve neyakakwana chip spacing uye kurongeka pasi pekupisa kwakasimba kutamisa kwakatsiga-mamiriro ekupisa ekufananidza mamiriro.Pasi peiyi nzvimbo uye chimiro, chigadzirwa chine yakanaka yekupisa kupisa kugona, yakaderera peak tembiricha, uye yakanyanya compact hunhu.

2.AuSn solderencapsulation process

Lumispot Tech inoshandisa nzira yekurongedza iyo inoshandisa AnSn solder pachinzvimbo chechinyakare indium solder kugadzirisa nyaya dzine chekuita nekuneta kwekupisa, electromigration, uye magetsi-kupisa kutama kunokonzerwa neindidium solder.Nekutora AuSn solder, kambani yedu ine chinangwa chekusimudzira kuvimbika kwechigadzirwa uye hupenyu hurefu.Kutsiviwa uku kunoitwa uku uchiona kuti nguva dzose bar stacks spacing, zvichiwedzera kubatsira mukuvandudzwa kwekuvimbika kwechigadzirwa uye hupenyu hurefu.

Mukugadzira tekinoroji yemhando yepamusoro-simba semiconductor pumped solid-state laser, indium (In) simbi yakagamuchirwa sechinhu chewelding nevagadziri vepasi rese nekuda kwekunakira kwayo kwenzvimbo yakaderera yekunyungudika, kuderera kwewelding kusagadzikana, kushanda kuri nyore, uye purasitiki yakanaka. deformation uye kupinda mukati.Nekudaro, kune semiconductor pumped solid state lasers pasi pekuenderera mberi kwekushanda kwekushandisa mamiriro, iyo alternating kusagadzikana inokonzeresa kuneta kuneta kweiyo indium welding layer, izvo zvinozotungamira mukukundikana kwechigadzirwa.Kunyanya mukupisa kwepamusoro uye kwakaderera uye kureba kwepulse hupamhi, chiyero chekutadza kwe indium welding chiri pachena.

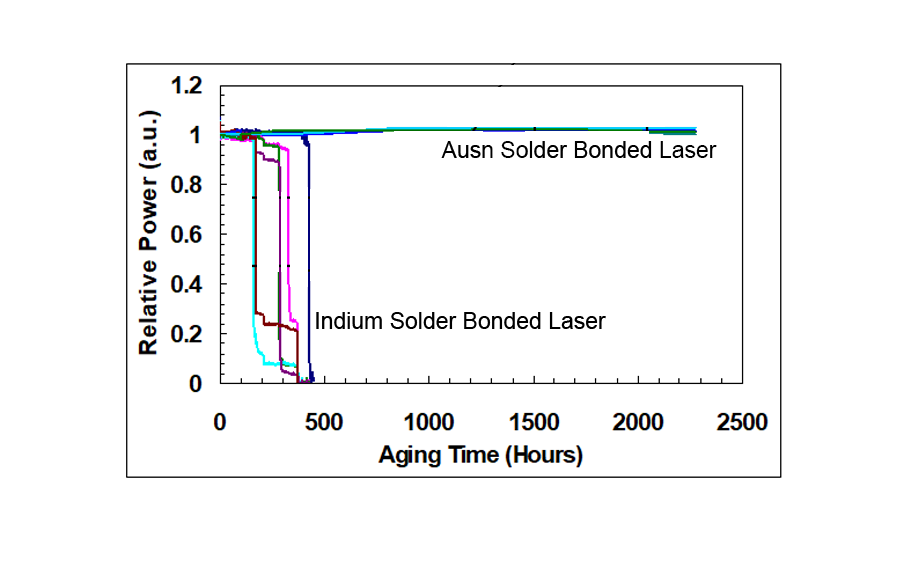

Kuenzanisa kweakawedzera hupenyu bvunzo dze lasers ane akasiyana solder mapakeji

Mushure memaawa 600 ekukwegura, zvigadzirwa zvose zvakaputirwa ne indium solder zvinokundikana;nepo zvigadzirwa zvakaputirwa nemarata egoridhe anoshanda kweanopfuura maawa e2,000 pasina kana shanduko musimba;kuratidza mabhenefiti eAuSn encapsulation.

Kuti uvandudze kuvimbika kweyepamusoro-simba semiconductor lasers uchichengetedza kuenderana kweakasiyana maratidziro ekuita, Lumispot Tech inotora Hard Solder (AuSn) semhando nyowani yekurongedza zvinhu.Kushandiswa kweiyo coefficient yekuwedzera kwekupisa kunofananidzwa ne substrate material (CTE-Matched Submount), iyo inobudirira kusunungurwa kwekushushikana kwekushisa, mhinduro yakanaka kumatambudziko eunyanzvi angasangana nawo mukugadzirira kwekuoma solder.Mamiriro anodiwa eiyo substrate material (submount) kuti ikwanise kutengeswa kune semiconductor chip is surface metallization.Surface metallization ndiko kuumbwa kwechidzitiro chekuparadzira barriers uye solder infiltration layer pamusoro peiyo substrate material.

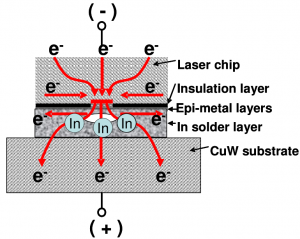

Schematic diagram ye electromigration mechanism ye laser yakavharidzirwa mu indium solder

Kuti uvandudze kuvimbika kweyepamusoro-simba semiconductor lasers uchichengetedza kuenderana kweakasiyana maratidziro ekuita, Lumispot Tech inotora Hard Solder (AuSn) semhando nyowani yekurongedza zvinhu.Kushandiswa kweiyo coefficient yekuwedzera kwekupisa kunofananidzwa ne substrate material (CTE-Matched Submount), iyo inobudirira kusunungurwa kwekushushikana kwekushisa, mhinduro yakanaka kumatambudziko eunyanzvi angasangana nawo mukugadzirira kwekuoma solder.Mamiriro anodiwa eiyo substrate material (submount) kuti ikwanise kutengeswa kune semiconductor chip is surface metallization.Surface metallization ndiko kuumbwa kwechidzitiro chekuparadzira barriers uye solder infiltration layer pamusoro peiyo substrate material.

Chinangwa chayo kune rumwe rutivi kuvhara solder kune substrate zvinhu diffusion, kune rumwe rutivi ndeyekusimbisa solder ne substrate zvinhu welding mano, kudzivirira solder layer yemhango.Surface metallization inogona zvakare kudzivirira iyo substrate zvinhu pamusoro oxidation uye mwando kupindira, kuderedza kusangana kuramba muwelding process, uye nekudaro inovandudza welding simba uye kuvimbika kwechigadzirwa.Iko kushandiswa kweiyo yakaoma solder AuSn seye welding zvinhu zve semiconductor pumped solid state lasers inogona kunyatso kudzivirira indium kusagadzikana kuneta, oxidation uye electro-thermal migration uye humwe hurema, zvakanyanya kuvandudza kuvimbika kwema semiconductor lasers pamwe nehupenyu hwesevhisi yelaser.Iko kushandiswa kwegoridhe-tin encapsulation tekinoroji kunogona kukunda matambudziko e electromigration uye electrothermal migration ye indium solder.

Mhinduro kubva kuLumispot Tech

Mune inoenderera kana pulsed lasers, kupisa kunokonzerwa nekutorwa kwepombi radiation ne laser medium uye kutonhora kwekunze kwepakati kunotungamira kune kusaenzana kwekushisa kugovera mukati me laser medium, zvichikonzera tembiricha gradients, zvichikonzera shanduko mune refractive index yepakati. uyezve kugadzira zvakasiyana-siyana zvekupisa.Iyo yekupisa yekuisa mukati meiyo yepakati inotungamira kune yekupisa lensing mhedzisiro uye thermally induced birefringence athari, iyo inoburitsa kumwe kurasikirwa mulaser system, inokanganisa kugadzikana kwelaser mugomba uye kunaka kweinobuda danda.Mune inoenderera ichimhanya laser system, iyo yekupisa kusagadzikana mune yekuwana yepakati inoshanduka sezvo simba repombi rinowedzera.Izvo zvakasiyana-siyana zvekupisa zvinokonzeresa muhurongwa zvinokanganisa zvakanyanya iyo yose laser system kuti iwane zvirinani beam mhando uye yepamusoro yekubuda simba, rinova rimwe rematambudziko anofanirwa kugadziriswa.Nzira yekudzivisa zvinobudirira uye kuderedza kupisa kwekristasi mukushanda kwekushanda, masayendisiti ave achinetseka kwenguva yakareba, yava imwe yezvino tsvakurudzo hotspots.

Nd: YAG laser ine thermal lens cavity

Mupurojekiti yekugadzira yakakwirira-simba LD-pumped Nd: YAG lasers, iyo Nd: YAG lasers ine thermal lensing cavity yakagadziriswa, kuitira kuti module inogona kuwana simba repamusoro ichiwana yakakwirira danda mhando.

Mune purojekiti yekugadzira yakakwirira-simba LD-pumped Nd: YAG laser, Lumispot Tech yakagadzira iyo G2-A module, iyo inogadzirisa zvakanyanya dambudziko rekushomeka kwesimba nekuda kweanopisa ane lens-ane cavities, ichibvumira iyo module kuwana simba rakawanda. nemhando yepamusoro yedanda.

Nguva yekutumira: Jul-24-2023