| Muchina wekuvhara zvidimbu zve Matanda eDiode Laser Bar | AuSn Yakarongedzwa |

| Hurefu hweMafungu epakati | 1064nm |

| Simba Rekuburitsa | ≥55W |

| Kushanda Kwazvino | ≤30 A |

| Kushanda kweVoltage | ≤24V |

| Kushanda Mode | CW |

| Kureba kweBuriji | 900mm |

| Girazi rinobuda | T = 20% |

| Kupisa Kwemvura | 25±3℃ |

Nyorera kuSocial Media Yedu Kuti Uwane Chiziviso Chinokurumidza

Kudiwa kwemamodule eCW (Continuous Wave) diode-pumped laser ari kuwedzera nekukurumidza senzvimbo yakakosha yekupomba ma lasers e solid-state. Mamodule aya anopa mabhenefiti akasiyana ekusangana nezvinodiwa zvema applications e solid-state laser. G2 - A Diode Pump Solid State Laser, chigadzirwa chitsva cheCW Diode Pump Series kubva kuLumiSpot Tech, ine nzvimbo yakakura yekushandisa uye kugona kushanda kuri nani.

Muchinyorwa chino, tichasanganisira zviri mukati zvinotarisa pamashandisirwo echigadzirwa, maficha echigadzirwa, uye zvakanakira chigadzirwa maererano neCW diode pump solid-state laser. Pakupera kwechinyorwa, ndicharatidza mushumo wekuyedza weCW DPL kubva kuLumispot Tech uye zvakanakira zvedu zvakakosha.

Munda weKunyorera

Malaser e semiconductor ane simba guru anonyanya kushandiswa semapombi emalaser e solid-state. Mukushanda kwakakodzera, sosi yekupomba ye semiconductor laser diode ndiyo yakakosha pakuvandudza tekinoroji ye laser diode-pumped solid-state laser.

Rudzi urwu rwelaser runoshandisa semiconductor laser ine simba rakagadzika rewavelength panzvimbo peKrypton kana Xenon Lamp yechinyakare kupomba makristaro. Nekuda kweizvozvo, iyi laser yakagadziridzwa inonzi 2ndkugadzirwa kweCW pombi laser (G2-A), iyo ine hunhu hwekushanda kwepamusoro, hupenyu hwebasa hurefu, mhando yakanaka yemwaranzi, kugadzikana kwakanaka, kuomarara uye miniaturization.

Kugona Kupomba Simba Repamusoro

CW Diode Pump Source inopa simba rakawanda remagetsi, ichinyatso pomba gain medium mu solid-state laser, kuti iite basa rakanakisisa re solid-state laser. Uyewo, simba rayo repamusoro-soro (kana simba repakati) rinoita kuti pave nemhando dzakasiyana dzemashandisirwo muindasitiri, mushonga, nesainzi.

Beam rakanaka uye kugadzikana

CW semiconductor pombing laser module ine mhando yepamusoro yemwenje wechiedza, ine kugadzikana kwega, izvo zvakakosha kuti chiedza chelaser chibudiswe nemazvo. Mamodule aya akagadzirwa kuti agadzire chimiro chemwenje chakanyatsotsanangurwa uye chakagadzikana, zvichiita kuti laser yakasimba ipombiwe uye igare yakavimbika. Ichi chinhu chinosangana zvakakwana nezvinodiwa zvekushandiswa kwelaser mukugadzirwa kwezvinhu zvemaindasitiri, kucheka nelaser, uye R&D.

Kushanda Kwemafungu Kusingaperi

Nzira yekushanda yeCW inosanganisa zvese zvakanaka zve continuous wavelength laser nePulsed Laser. Musiyano mukuru uripo pakati peCW Laser nePulsed laser isimba rinobuda.CW Laser, inozivikanwawo seContinuous wave laser, ine hunhu hwekushanda kwakagadzikana uye kugona kutumira continuous wave.

Dhizaini Yakabatana uye Yakavimbika

CW DPL inogona kubatanidzwa zviri nyore mumagetsi aripolaser yakasimba-statezvichienderana nedhizaini uye chimiro chayo chidiki. Kugadzirwa kwayo kwakasimba uye zvinhu zvemhando yepamusoro zvinovimbisa kuvimbika kwenguva refu, zvichideredza mari yekushanda uye yekugadzirisa, izvo zvinonyanya kukosha mukugadzira maindasitiri uye maitiro ekurapa.

Kudiwa Kwemusika kweDPL - Mikana Yekukura Kwemusika

Sezvo kudiwa kwema-solid-state lasers kuri kuramba kuchiwedzera mumaindasitiri akasiyana, kudiwa kwema-high-performance pombi sources akadai seCW diode-pumped laser modules kuri kuwedzerawo. Maindasitiri akaita sekugadzira, hutano, dziviriro, uye tsvakurudzo yesainzi anovimba nema-solid-state lasers kuti ashandise nemazvo.

Mukupfupikisa, senzvimbo yekupomba diode ye solid-state laser, hunhu hwezvigadzirwa: kugona kupomba nesimba guru, CW operation mode, mhando yepamusoro ye beam uye kugadzikana, uye dhizaini yakagadzikana, zvinowedzera kudiwa kwemusika muma laser modules aya. Semutengesi, Lumispot Tech inoisawo simba rakawanda mukuvandudza mashandiro uye matekinoroji anoshandiswa muDPL series.

Seti yeZvigadzirwa zveG2-A DPL Kubva kuLumispot Tech

Seti yega yega yezvigadzirwa ine mapoka matatu emamodules emhando dzakatarwa dzakatenderedzwa, boka rega rega remamodules emhando dzakatarwa dzakatenderedzwa (Horizontal Stacked Array modules) simba rekupomba rinosvika 100W@25A, uye simba rekupomba rinosvika 300W@25A.

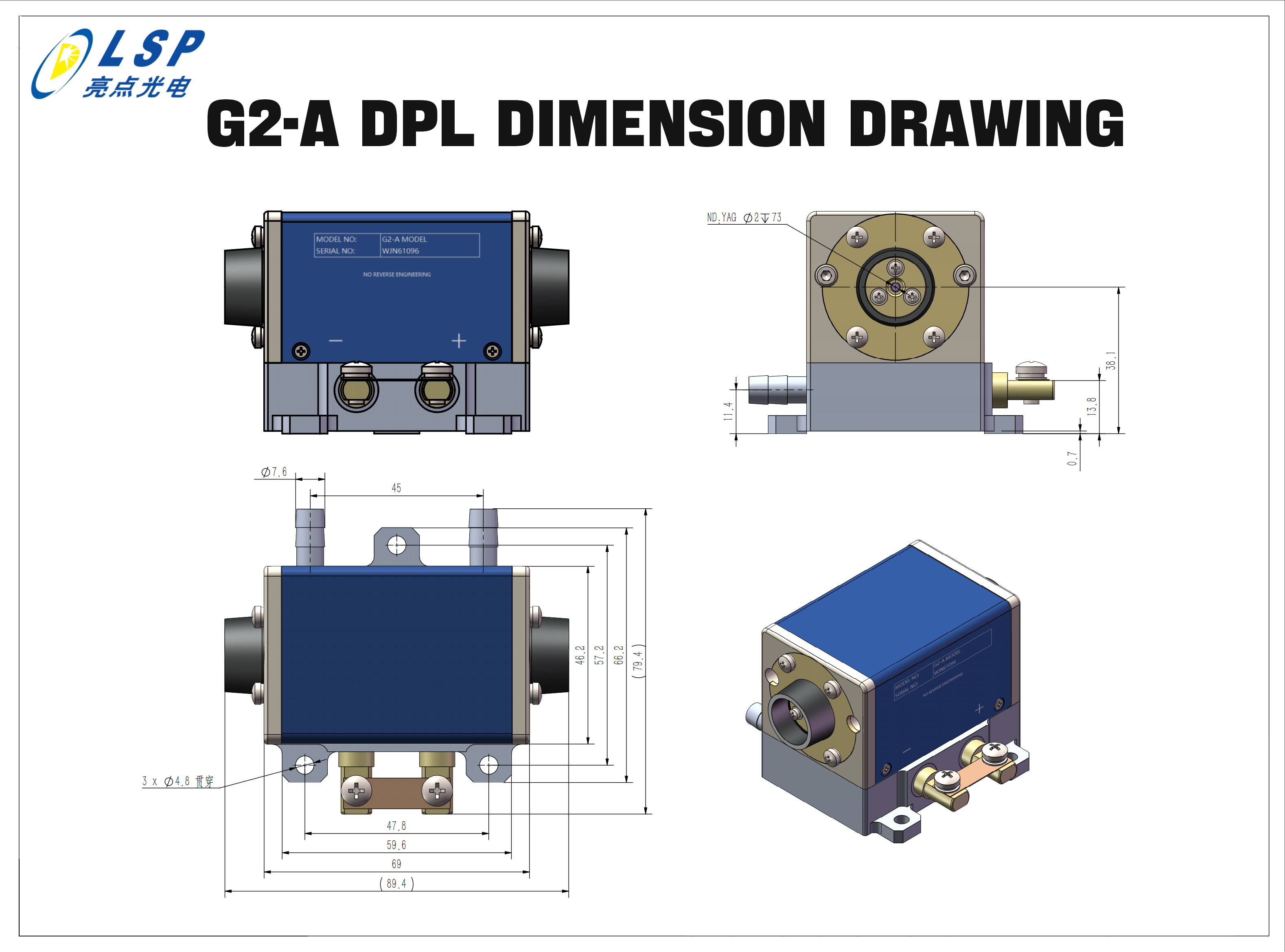

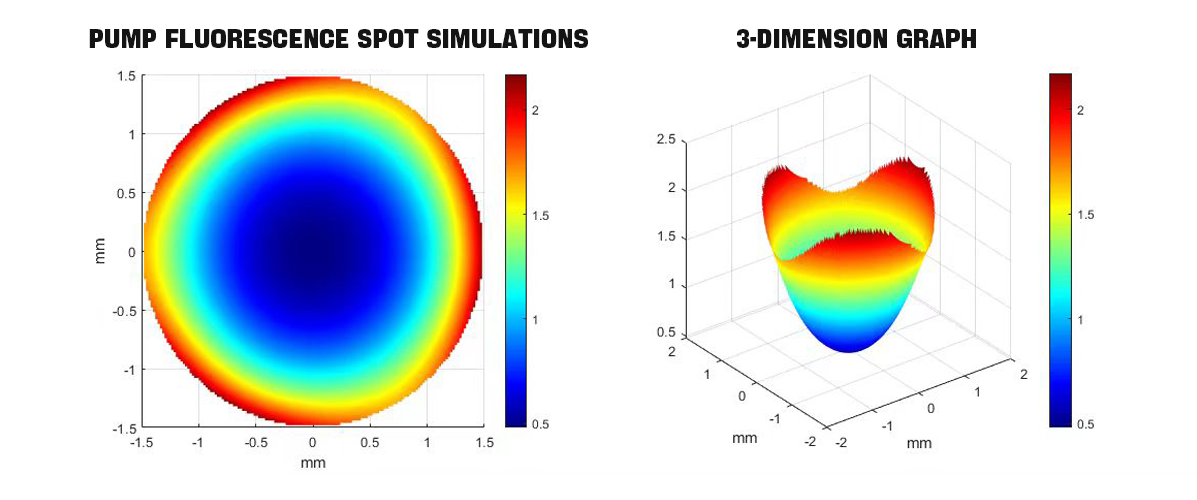

Nzvimbo yekupenya kwepombi yeG2-A inoratidzwa pazasi:

Ruzivo Rukuru rweUnyanzvi rweG2-A Diode Pump Solid State Laser:

Simba Redu MuTekinoroji

1. Tekinoroji Yekutarisira Kupisa Kwenguva Pfupi

MaLaser eSemiconductor-pumped solid-state anoshandiswa zvakanyanya pakushandisa mawave (CW) ane simba rinobuda zvakanyanya uye mawave (CW) ane simba rinobuda zvakanyanya. MumaLaser aya, kukwirira kwethermal sink uye daro riri pakati pemachips (kureva, ukobvu hwesubstrate nechip) zvinokanganisa zvakanyanya kugona kwekupisa kwechigadzirwa. Kureba kukuru kwechip-to-chip kunoita kuti kupisa kupararire zviri nani asi kunowedzera huwandu hwechigadzirwa. Kusiyana neizvi, kana nzvimbo yechip ikaderedzwa, saizi yechigadzirwa ichaderedzwa, asi kugona kwekupisa kwechigadzirwa kunogona kusakwana. Kushandisa vhoriyamu yakamanikana kugadzira laser ye semiconductor-pumped solid-state inosangana nezvinodiwa zvekupisa ibasa rakaoma mukugadzira.

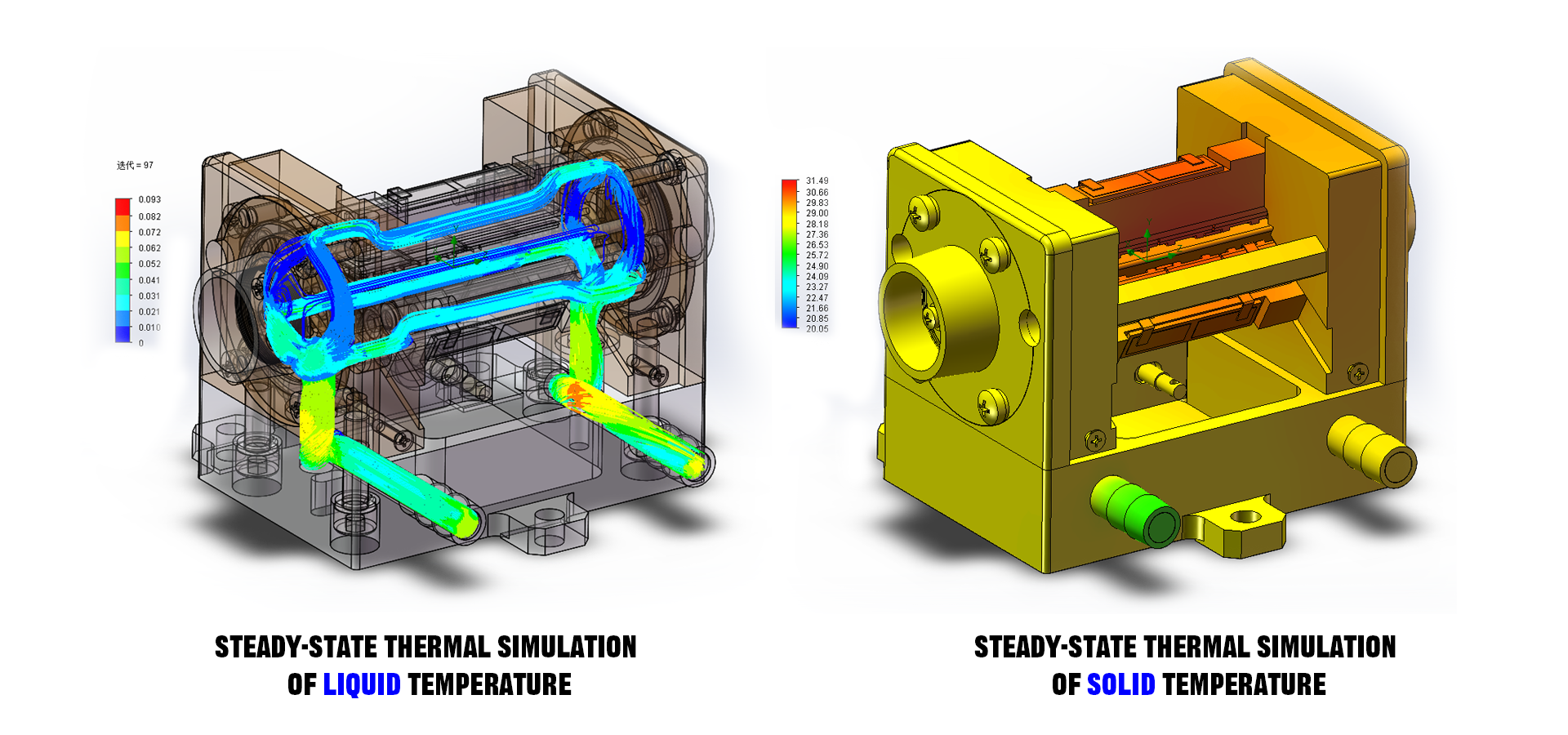

Girafu Yekutevedzera Kupisa Kwemamiriro Ekunze

Lumispot Tech inoshandisa nzira ye finite element kutevedzera nekuverenga nzvimbo yekupisa yemudziyo. Musanganiswa we solid heat transfer steady-state thermal simulation uye liquid temperature simulation inoshandiswa pakufananidzira kwekupisa. Kune mamiriro ekushanda anoenderera mberi, sezvakaratidzwa mumufananidzo uri pazasi: chigadzirwa chinokurudzirwa kuti chive nenzvimbo yakakwana ye chip spacing uye kurongeka pasi pemamiriro ekufananidzira kwekupisa kwe solid heat transfer steady-state. Pasi penzvimbo iyi uye chimiro, chigadzirwa chine kugona kwakanaka kwekupisa, tembiricha yakaderera, uye hunhu hwakanyanya kupfupika.

2.AuSn soldermaitiro ekuvhara

Lumispot Tech inoshandisa nzira yekurongedza inoshandisa AnSn solder panzvimbo peindium solder yechinyakare kugadzirisa matambudziko ane chekuita nekuneta kwekupisa, electromigration, uye kufamba kwemagetsi-kupisa kunokonzerwa neindium solder. Nekushandisa AuSn solder, kambani yedu ine chinangwa chekusimudzira kuvimbika kwechigadzirwa uye kugara kwenguva refu. Kutsiva uku kunoitwa uku tichiona kuti nzvimbo dziri pakati pemabhawa dzakagara dziripo, zvichibatsirawo mukuvandudza kuvimbika kwechigadzirwa uye hupenyu hwacho.

Mu tekinoroji yekurongedza ye laser ine simba guru re semiconductor pumped solid-state, indium (In) metal yakagamuchirwa sewelding material nevagadziri vepasi rose nekuda kwekubatsira kwayo kwekunyunguduka kushoma, kushushikana kwewelding kushoma, kushanda kuri nyore, uye plastic deformation yakanaka uye kupinda mukati. Zvisinei, kune semiconductor pumped solid state lasers pasi pemamiriro ekushandisa nguva dzose, kushushikana kunochinjana kunokonzera kuneta kwe stress ye indium welding layer, izvo zvinozotungamira kukundikana kwechigadzirwa. Kunyanya mukupisa kwakanyanya uye kwakaderera uye kureba kwe pulse widths, mwero wekukundikana kwe indium welding uri pachena.

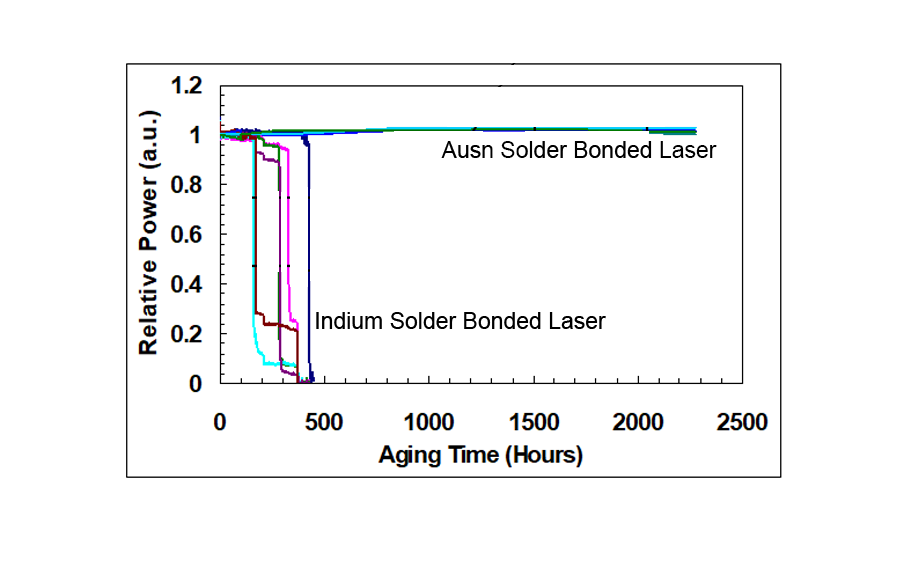

Kuenzanisa kwemiedzo yehupenyu hwakakurumidza yema lasers nemapakeji akasiyana e solder

Mushure memaawa mazana matanhatu ekukwegura, zvigadzirwa zvese zvakaputirwa neindium solder zvinokundikana; nepo zvigadzirwa zvakaputirwa negoridhe tin zvichishanda kwemaawa anopfuura 2,000 pasina shanduko musimba; zvichiratidza zvakanakira zveAuSn encapsulation.

Kuti ivandudze kuvimbika kwema-laser e-semiconductor ane simba guru uku ichichengetedza kuenderana kwezviratidzo zvakasiyana-siyana zvekushanda, Lumispot Tech inoshandisa Hard Solder (AuSn) semhando itsva yezvinhu zvekurongedza. Kushandiswa kwe coefficient ye thermal expansion material matched substrate material (CTE-Matched Submount), kuburitsa zvinobudirira kwe thermal stress, mhinduro yakanaka kumatambudziko ehunyanzvi angangosangana nawo pakugadzira hard solder. Chinodiwa kuti substrate material (submount) ikwanise kusungirirwa kune semiconductor chip ndeye surface metallization. Surface metallization kuumbwa kwe layer ye diffusion barrier uye solder infiltration layer pamusoro pe substrate material.

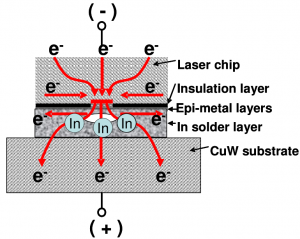

Dhiyagiramu yemufananidzo wemagetsi ekufambisa kwelaser yakaputirwa mu indium solder

Kuti ivandudze kuvimbika kwema-laser e-semiconductor ane simba guru uku ichichengetedza kuenderana kwezviratidzo zvakasiyana-siyana zvekushanda, Lumispot Tech inoshandisa Hard Solder (AuSn) semhando itsva yezvinhu zvekurongedza. Kushandiswa kwe coefficient ye thermal expansion material matched substrate material (CTE-Matched Submount), kuburitsa zvinobudirira kwe thermal stress, mhinduro yakanaka kumatambudziko ehunyanzvi angangosangana nawo pakugadzira hard solder. Chinodiwa kuti substrate material (submount) ikwanise kusungirirwa kune semiconductor chip ndeye surface metallization. Surface metallization kuumbwa kwe layer ye diffusion barrier uye solder infiltration layer pamusoro pe substrate material.

Chinangwa chayo ndechekuvhara kupararira kwechinhu chinosungirirwa muchinhu chinosungirirwa muchinhu, kune rumwe rutivi ndechekusimbisa chinhu chinosungirirwa nemuchina wekubatanidza zvinhu, kudzivirira kupararira kwechinhu chinosungirirwa muchinhu chinosungirirwa mugomba. Kugadziriswa kwesimbi pamusoro pechinhu kunogonawo kudzivirira kusvibiswa kwechinhu chinosungirirwa muchinhu uye kupinda kwehunyoro, kuderedza kuramba kwekubatana mukuita kwekubatanidza, uye nokudaro kuvandudza simba rekubatanidza uye kuvimbika kwechigadzirwa. Kushandiswa kweAuSn inosungirirwa muchinhu chinosungirirwa muchinhu chinosungirirwa muchinhu chinotenderedzwa ...

Mhinduro Kubva kuLumispot Tech

Muma laser anoenderera mberi kana kuti anotenderera, kupisa kunokonzerwa nekutorwa kwemwaranzi yepombi ne laser medium uye kutonhora kwekunze kwe medium kunotungamira mukupararira kwekushisa kusina kufanana mukati me laser medium, zvichikonzera kuchinja kwe refractive index ye medium uye zvobva zvagadzira mhedzisiro dzakasiyana dzekupisa. Kuiswa kwekupisa mukati me gain medium kunotungamira ku thermal lensing effect uye thermally induced birefringence effect, iyo inokonzera kurasikirwa kwakati mu laser system, ichikanganisa kugadzikana kwe laser mu cavity uye mhando ye output beam. Mu laser system inoramba ichishanda, thermal stress mu gain medium inochinja sezvo simba repombi richiwedzera. Thermal effects dzakasiyana mu system inokanganisa zvakanyanya laser system yese kuti iwane beam quality iri nani uye high output power, inova imwe yematambudziko anofanira kugadziriswa. Maitiro ekudzivirira uye kuderedza thermal effect yemakristaro mukushanda, masayendisiti ave achinetseka kwenguva yakareba, yave imwe yenzvimbo dziripo dzekutsvaga.

Nd:YAG laser ine thermal lens cavity

Muchirongwa chekugadzira ma-laser eNd:YAG ane simba guru reLD-pumped, ma-laser eNd:YAG ane thermal lensing cavity akagadziriswa, kuitira kuti module iwane simba guru uku ichiwana mwenje wepamusoro.

Muchirongwa chekugadzira laser ine simba guru reLD-pomped Nd:YAG, Lumispot Tech yakagadzira module yeG2-A, iyo inogadzirisa zvakanyanya dambudziko rekushomeka kwesimba nekuda kwemakomba ane magirazi ekupisa, zvichiita kuti module iwane simba rakawanda rine mwenje wepamusoro.

Nguva yekutumira: Chikunguru-24-2023