Nyorera kuSocial Media Yedu Kuti Uwane Chiziviso Chinokurumidza

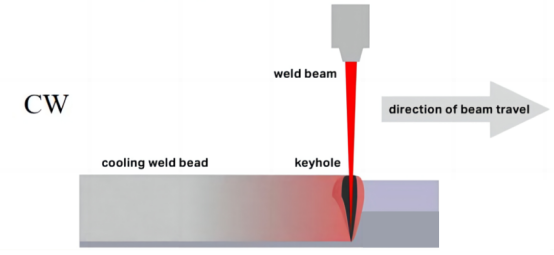

Laser Inoenderera Mberi Yemafungu

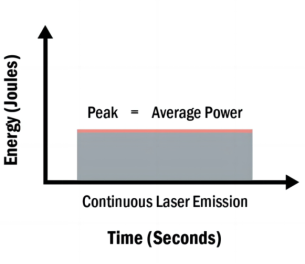

CW, chipfupiso che "Continuous Wave," chinoreva masisitimu elaser anokwanisa kupa simba relaser risingadzoreki panguva yekushanda. Dzichiratidzwa nekukwanisa kwadzo kuburitsa laser nguva dzose kusvika kushanda kwapera, malaser eCW anosiyaniswa nesimba rawo repamusoro uye simba repakati rakakwirira kana tichienzanisa nemamwe marudzi emalaser.

Mashandisirwo akasiyana-siyana

Nekuda kwekushanda kwavo nguva dzose, ma-laser eCW anoshandiswa zvakanyanya muminda yakadai sekucheka simbi nekusanganisa mhangura nearuminiyamu, zvichiita kuti ave pakati pemhando dzema-laser dzinonyanya kushandiswa uye dzinoshandiswa zvakanyanya. Kugona kwavo kupa simba rakasimba uye risingaperi kunoita kuti vasakoshe mukugadzirisa nemazvo uye mukugadzirwa kwezvinhu zvakawanda.

Magadzirirwo Ekugadzirisa Maitiro

Kugadzirisa laser yeCW kuti ishande zvakanaka kunosanganisira kutarisa pane zvakakosha zvakasiyana-siyana, kusanganisira simba remagetsi, huwandu hwe defocus, dhayamita ye beam spot, uye kumhanya kwekugadzirisa. Kugadzirisa ma parameter aya kwakakosha kuti uwane mhedzisiro yakanaka yekugadzirisa, kuve nechokwadi chekuti mashandiro e laser anoshanda zvakanaka uye ane hunhu.

Dhizaini yeSimba reLaser Rinoenderera Mberi

Hunhu hwekugovera Simba

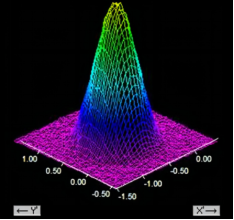

Chinhu chinonyanya kukosha chema-laser eCW ndiko kugoverwa kwawo kwesimba reGaussian, uko kugoverwa kwesimba kwechikamu chelaser chinoderera kubva pakati kuenda kunze nenzira yeGaussian (normal distribution). Hunhu uhwu hwekugoverwa hunobvumira ma-laser eCW kuwana kunyatsojeka kwakanyanya uye kushanda zvakanaka, kunyanya mumashandisirwo anoda kuiswa kwesimba rakawanda.

Dhayagiramu Yekugovera Simba reLaser yeCW

Mabhenefiti eContinuous Wave (CW) Laser Welding

Maonero eZvivako Zvidiki

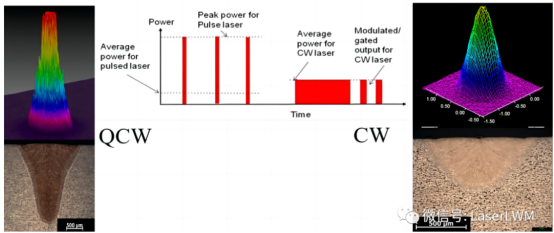

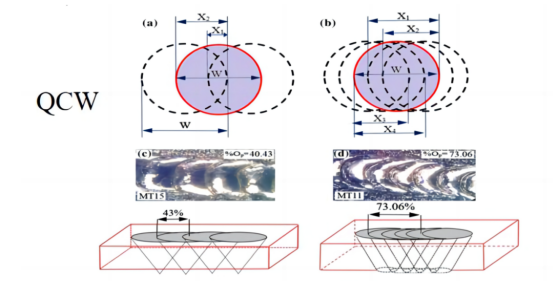

Kuongorora magadzirirwo esimbi kunoratidza mabhenefiti akasiyana eContinuous Wave (CW) laser welding pamusoro peQuasi-Continuous Wave (QCW) pulse welding. QCW pulse welding, inodziviswa nemuganhu wayo wefrequency, kazhinji inenge 500Hz, inotarisana nekuchinjana pakati pehuwandu hwe overlap uye hurefu hwekupinda. Kupindirana kwakaderera kunoita kuti pave nekudzika kusina kukwana, nepo huwandu hwe overlap hunoderedza kumhanya kwe welding, zvichideredza kushanda zvakanaka. Kusiyana neizvi, CW laser welding, kuburikidza nekusarudza diameters dzakakodzera dze laser core uye misoro ye welding, inoita kuti pave nekuwirirana kunoshanda uye kunoramba kuripo. Nzira iyi inoratidza kuva yakavimbika zvikuru mukushandiswa kunoda high seal integrity.

Kufunga Nezvekukanganiswa Kwekupisa

Panyaya yekukanganiswa nekupisa, welding yeQCW pulse laser ine dambudziko rekubatana, zvichikonzera kupisa kwe weld seam kakawanda. Izvi zvinogona kukonzera kusawirirana pakati pemaumbirwo esimbi nezvinhu zvepakutanga, kusanganisira kusiyana kwehukuru hwekudonha kwesimbi uye mwero wekutonhora, nokudaro zvichiwedzera njodzi yekutsemuka. Welding yeCW laser, kune rumwe rutivi, inodzivirira dambudziko iri nekupa maitiro akafanana uye anoramba achidziya.

Nyore Yekugadzirisa

Panyaya yekushanda nekugadzirisa, QCW laser welding inoda kugadziriswa kwakanyatsonaka kwezviyero zvakasiyana-siyana, kusanganisira frequency yekudzokorora kwepulse, simba repamusoro, upamhi hwepulse, duty cycle, nezvimwewo. CW laser welding inoita kuti maitiro ekugadzirisa ave nyore, ichinyanya kutarisa pa waveform, kumhanya, simba, uye defocus, zvichiita kuti kuoma kwekushanda kuve nyore.

Kufambira Mberi Kwetekinoroji Mukugadzira CW Laser Welding

Kunyange zvazvo QCW laser welding ichizivikanwa nesimba rayo guru uye kupisa kwakaderera, inobatsira pakushongedza zvinhu zvinonzwa kupisa uye zvinhu zvakatetepa zvikuru, kufambira mberi mune tekinoroji yeCW laser welding, kunyanya kune mashandisirwo ane simba guru (kazhinji anopfuura 500 watts) uye deep penetration welding zvichibva pamhedzisiro yekiyi, zvakawedzera zvakanyanya huwandu hwekushandiswa kwayo uye kushanda kwayo. Rudzi urwu rwelaser rwakakodzera zvakanyanya zvinhu zvakakora kupfuura 1mm, zvichiwana high aspect ratios (inopfuura 8:1) kunyangwe kupisa kwakawanda kuchiiswa.

Kukwesha kweLaser kweQuasi-Continuous Wave (QCW)

Kugoverwa Kwesimba Rakatarisana

QCW, zvinoreva kuti "Quasi-Continuous Wave," inomiririra tekinoroji yelaser apo laser inoburitsa chiedza nenzira isingachinji, sezvakaratidzwa mumufananidzo a. Kusiyana nekugoverwa kwesimba kwakafanana kwema single-mode continuous lasers, ma QCW lasers anosimbisa simba rawo zvakanyanya. Hunhu uhwu hunopa ma QCW lasers simba rakawanda, zvichishandura kugona kwakasimba kwekupinda. Mhedzisiro yesimbi inoguma yakafanana nechimiro che "nail" chine chiyero chakakosha chekudzika kusvika paupamhi, zvichibvumira ma QCW lasers kuti abudirire mukushandiswa kunosanganisira high-reflection alloys, zvinhu zvinonzwa kupisa, uye precision micro-welding.

Kugadzikana Kwakawedzerwa uye Kuderedzwa Kwekupindirana Kwemapombi

Chimwe chezvakanakira zveQCW laser welding kugona kwayo kuderedza mhedzisiro yesimbi plume padanho rekunyudzwa kwezvinhu, zvichikonzera maitiro akagadzikana. Munguva yekudyidzana kwezvinhu nelaser, kupwanya kwakanyanya kunogona kugadzira musanganiswa wesimbi vapor neplasma pamusoro pedziva rakanyunguduka, rinowanzozivikanwa sesimbi plume. Iyi plume inogona kudzivirira pamusoro pechinhu kubva kune laser, zvichikonzera kuburitswa kwesimba kusina kugadzikana uye zvikanganiso zvakaita sekupararira, nzvimbo dzekuputika, uye makomba. Zvisinei, kubuda kweQCW lasers nguva nenguva (semuenzaniso, kuputika kwe5ms kunoteverwa ne10ms pause) kunoita kuti laser yega yega isvike pamusoro pechinhu isina kukanganiswa nesimbi plume, zvichikonzera maitiro akagadzikana ewelding, anobatsira zvikuru pakuwelding kwetin-sheet.

Simba reDziva reStable Melt

Maitiro edziva rinonyunguduka, kunyanya kana tichitarisa masimba anoshanda paburi rekiyi, akakosha pakuona mhando yeweld. Malaser anoenderera mberi, nekuda kwekugara kwenguva refu uye nzvimbo dzakakura dzinokanganiswa nekupisa, anowanzogadzira madziva makuru anonyunguduka azere nesimbi yemvura. Izvi zvinogona kutungamira kune zvikanganiso zvine chekuita nemadziva makuru anonyunguduka, akadai sekudonha kweburi rekiyi. Kusiyana neizvi, simba rakatarisana uye nguva pfupi yekudyidzana kweQCW laser welding zvinosimbisa dziva rinonyunguduka rakatenderedza buri rekiyi, zvichikonzera kupararira kwesimba kwakafanana uye kuwanda kwekuvhunika, kutsemuka, uye kupararira.

Nzvimbo Yakaderedzwa Inokonzerwa Nekupisa (HAZ)

Kuchinjika kwelaser kunoenderera mberi kunoita kuti zvinhu zvigare zvichipisa, zvichikonzera kuti kupisa kupfuure zvakanyanya muzvinhu zvacho. Izvi zvinogona kukonzera kushanduka kwekupisa kusingadiwe uye zvikanganiso zvinokonzerwa nekushushikana muzvinhu zvitete. Malaser eQCW, nekushanda kwawo nguva nenguva, anobvumira zvinhu kuti zvitonhore, nokudaro zvichideredza nzvimbo inokanganiswa nekupisa uye kupinda kwekupisa. Izvi zvinoita kuti QCW laser welding ive yakakodzera zvakanyanya kune zvinhu zvitete uye izvo zviri pedyo nekupisa.

Simba Repamusorosoro

Kunyangwe iine simba rakaenzana nerema laser anoenderera mberi, maQCW lasers ane simba repamusoro uye huwandu hwesimba, zvichikonzera kupinda kwakadzika uye kugona kwakasimba kwewelding. Izvi zvinonyanya kuoneka mukusungirirwa kwemapepa matete emhangura nearuminiyamu. Kusiyana neizvi, ma continuous lasers ane simba rakaenzana repakati anogona kutadza kuita chiratidzo pamusoro pechinhu nekuda kwekushomeka kwesimba, zvichikonzera kuratidzwa. Ma high-power continuous lasers, kunyange zvazvo achikwanisa kunyungudutsa chinhu, anogona kuwedzera zvakanyanya mu absorption rate mushure mekunyunguduka, zvichikonzera kudzika kusingadzoreki kwekunyunguduka uye kupisa, izvo zvisina kukodzera ku thin-sheet welding uye zvinogona kukonzera kusaiswa kwemavara kana kupisa, zvichitadza kusangana nezvinodiwa zvemaitiro.

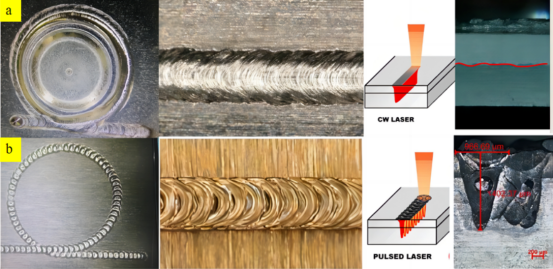

Kuenzanisa kwemhedzisiro yekuwelding pakati peCW neQCW lasers

a. Laser yeRaser Inoramba Ichienderera (CW):

- Chitarisiko chenzara yakavharirwa nelaser

- Kuonekwa kwemusono we weld wakatwasuka

- Dhayagiramu yechirongwa chekubuda kwelaser

- Chikamu chemuchinjiko cherefu

b. Quasi-Continuous Wave (QCW) Laser:

- Chitarisiko chenzara yakavharirwa nelaser

- Kuonekwa kwemusono we weld wakatwasuka

- Dhayagiramu yechirongwa chekubuda kwelaser

- Chikamu chemuchinjiko cherefu

- * Kwakabva: Nyaya yakanyorwa naWilldong, kuburikidza neWeChat Public Account LaserLWM.

- * Chinongedzo chechinyorwa chekutanga: https://mp.weixin.qq.com/s/8uCC5jARz3dcgP4zusu-FA.

- Zviri muchinyorwa chino ndezvekudzidza nekutaurirana chete, uye kodzero dzese dzemunyori wekutanga ndedzemunyori wekutanga. Kana paine kutyorwa kwekodzero dzemunyori, ndapota taura nesu kuti tibvise.

Laser yeQCW kubva kuLumispot Tech:

Laser yeCW:

Nguva yekutumira: Kurume-05-2024