Nyorera kuSocial Media Yedu Kuti Uwane Chiziviso Chinokurumidza

Mukugadzira michina yelaser chaiyo, kudzora nharaunda kwakakosha. Kumakambani akaita seLumispot Tech, iyo inotarisa pakugadzira malaser emhando yepamusoro, kuve nechokwadi chekuti nzvimbo yekugadzira haina guruva haisiyo chete chiyero - kuzvipira kune mhando uye kugutsikana kwevatengi.

Chii chinonzi sutu yemukamuri rekuchenesa?

Nguo yekuchenesa, inozivikanwawo sesutu yekuchenesa, suti yetsuro, kana kuti machira ekuvhara, zvipfeko zvakagadzirwa kuti zvidzivise kuburitswa kwetsvina nezvinhu zvidiki munzvimbo yekuchenesa. Makamuri ekuchenesa inzvimbo dzinodzorwa dzinoshandiswa muminda yesainzi nemaindasitiri, senge kugadzira semiconductor, biotechnology, mishonga, uye ndege, uko huwandu hwakaderera hwezvinhu zvinosvibisa zvakaita seguruva, hutachiona hwemhepo, uye zvikamu zveaerosol zvakakosha pakuchengetedza mhando uye kunaka kwezvigadzirwa.

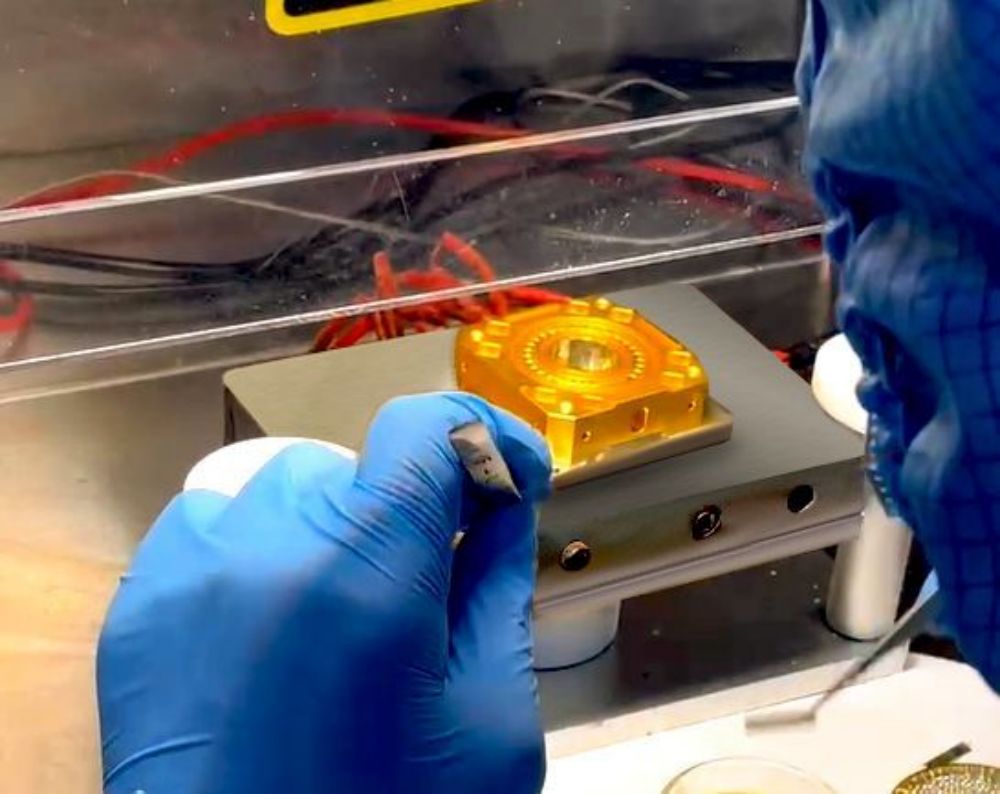

Vashandi veR&D muLumispot Tech

Nei Zvipfeko Zvekuchenesa Zvichidiwa?

Kubva payakavambwa muna 2010, Lumispot Tech yave nekugadzira michina yemhando yepamusoro, isina guruva munzvimbo yayo ine 14,000-square-foot. Vashandi vese vanopinda munzvimbo yekugadzira vanofanirwa kupfeka mbatya dzakachena dzinoenderana nezvinodiwa nemutemo. Iyi tsika inoratidza hutungamiriri hwedu hwemhando yepamusoro uye kutarisisa maitiro ekugadzira.

Kukosha kwembatya dzisina guruva dzemuworkshop kunonyanya kuratidzwa muzvinhu zvinotevera:

Imba Yekushambidza muLumispot Tech

Kuderedza Magetsi Asingachinji

Machira anoshandiswa muzvipfeko zvemukamuri rekuchenesa anowanzo sanganisira tambo dzinofambisa mhepo kudzivirira kuungana kwemagetsi asingachinji, izvo zvinogona kukuvadza zvikamu zvemagetsi zvinonzwa kana kupisa zvinhu zvinobvira moto. Magadzirirwo ezvipfeko izvi anoita kuti njodzi dzemagetsi asingachinji (ESD) dzideredzwe (Chubb, 2008).

Kudzora Kusvibiswa:

Mbatya dzemukamuri rekuchenesa dzinogadzirwa nemachira akakosha anodzivirira kudonha kwemafaibha kana zvidimbu uye anodzivirira kuungana kwemagetsi asingachinji anogona kukwezva guruva. Izvi zvinobatsira kuchengetedza mwero wakasimba wehutsanana unodiwa mumakamuri ekuchenesa uko kunyange zvidimbu zvidiki zvinogona kukonzera kukuvara kukuru kuma microprocessors, microchips, zvigadzirwa zvemishonga, uye mamwe matekinoroji anonyanya kusimba.

Kuvimbika Kwechigadzirwa:

Mumabasa ekugadzira apo zvigadzirwa zvinokanganiswa zvakanyanya nekusvibiswa kwezvakatipoteredza (senge mukugadzira semiconductor kana kugadzira mishonga), mbatya dzemumba dzakachena dzinobatsira kuona kuti zvigadzirwa zvinogadzirwa munzvimbo isina kusvibiswa. Izvi zvakakosha pakushanda uye kuvimbika kwezvikamu zvetekinoroji yepamusoro uye kuchengetedzeka kwehutano mumishonga.

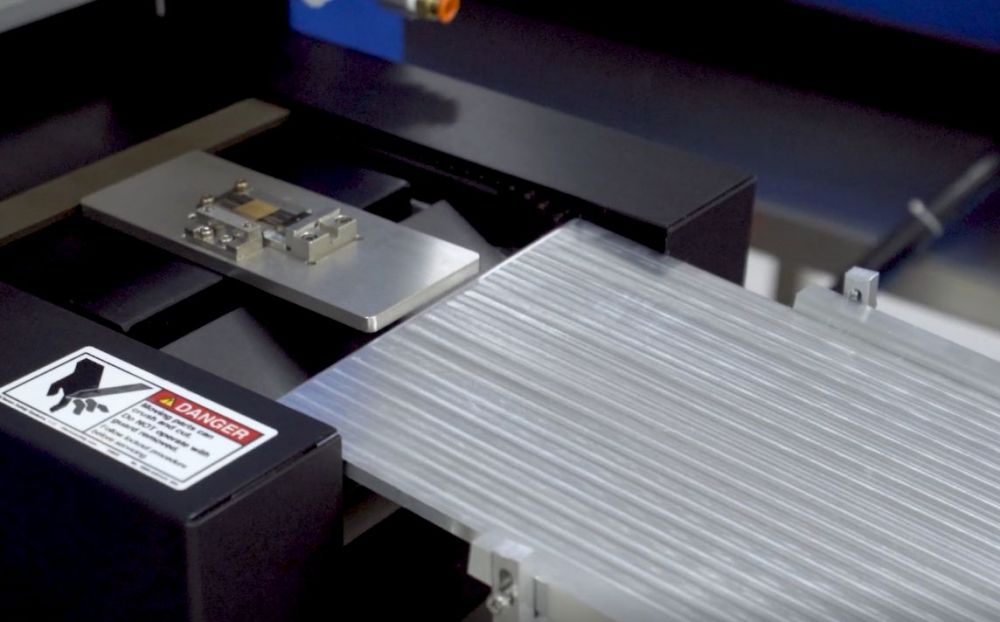

Lumispot Tech'sLaser Diode Bar ArrayMaitiro Ekugadzira

Kuchengetedzeka uye Kutevedzera Mutemo:

Kushandiswa kwembatya dzekuchenesa kunorayirwawo nemitemo yakatarwa nemasangano akadai seISO (International Organisation for Standardization) iyo inoronga dzimba dzekuchenesa zvichienderana nehuwandu hwezvinhu zvinobvumirwa pa cubic mita imwe neimwe yemhepo. Vashandi vari mudzimba dzekuchenesa vanofanirwa kupfeka mbatya idzi kuti vatevedzere mitemo iyi uye kuti vave nechokwadi chekuti chigadzirwa nevashandi vakachengeteka, kunyanya pavanenge vachibata zvinhu zvine njodzi (Hu & Shiue, 2016).

Kupatsanurwa Kwembatya Dzekuchenesa

Matanho Ekupatsanura: Mbatya dzemumba dzekuchenesa dzinotangira pamhando dzakaderera seClass 10000, dzakakodzera nzvimbo dzisina kuomarara, kusvika kumhando dzepamusoro seClass 10, dzinoshandiswa munzvimbo dzine njodzi huru nekuda kwekugona kwadzo kudzora kusvibiswa kwezvimedu (Boone, 1998).

Zvipfeko zveKirasi 10 (ISO 3):Zvipfeko izvi zvakakodzera munzvimbo dzinoda kuchena kwakanyanya, zvakaita sekugadzirwa kwema laser system, optical fibers, uye precision optics. Zvipfeko zveClass 10 zvinonyatsovhara zvidimbu zvakakura kupfuura 0.3 micrometers.

Zvipfeko zveKirasi 100 (ISO 5):Zvipfeko izvi zvinoshandiswa mukugadzira zvinhu zvemagetsi, zviratidziro zve flat-panel, nezvimwe zvigadzirwa zvinoda kuchena kwakanyanya. Zvipfeko zveClass 100 zvinogona kuvhara zvidimbu zvakakura kupfuura 0.5 micrometer.

Zvipfeko zveKirasi 1000 (ISO 6):Zvipfeko izvi zvakakodzera nzvimbo dzine zvinodiwa zvehutsanana huri pakati nepakati, zvakaita sekugadzirwa kwezvinhu zvemagetsi nemidziyo yekurapa.

Zvipfeko zveKirasi 10,000 (ISO 7):Zvipfeko izvi zvinoshandiswa munzvimbo dzemaindasitiri dzine zvinodiwa zvishoma zvekuchena.

Zvipfeko zvekuchenesa zvinowanzo sanganisira mahood, mamasiki ekumeso, bhutsu, macoverall, uye magirovhosi, zvese zvakagadzirirwa kufukidza ganda rakavhurika zvakanyanya sezvinobvira uye kudzivirira muviri wemunhu, unova ndiwo tsime guru rezvinhu zvinosvibisa, kuti usapinze zvidimbu munzvimbo inodzorwa.

Kushandiswa muOptical uye Laser Production Workshops

Munzvimbo dzakadai sekugadzira ma optics ne laser, mbatya dzekuchenesa dzinowanzo fanirwa kusangana nezvinodiwa zvepamusoro, kazhinji Kirasi 100 kana kunyange Kirasi 10. Izvi zvinoita kuti pasave nekupindirana kushoma kwezvikamu zve optical zvinonzwa uye masisitimu e laser, izvo zvinogona kukonzera matambudziko makuru emhando uye mashandiro (Stowers, 1999).

Vashandi veLumispot Tech vachishanda paQCWMatanda eDiode eLaser akabatana.

Zvipfeko izvi zvekuchenesa zvakagadzirwa nemachira ekuchenesa akasiyana-siyana anopa guruva rakanaka uye simba rekudzivirira kusvibiswa. Magadzirirwo ezvipfeko izvi akakosha pakuchengetedza kuchena. Zvinhu zvakaita semacuffs nemagumbo zvinonyatsobatanidzwa, pamwe nemazipi anotambanuka kusvika pakora, zvinoshandiswa kudzivirira kusvibiswa kunopinda munzvimbo yakachena.

Referensi

Boone, W. (1998). Kuongororwa kwemachira ezvipfeko zvemukamuri rekuchenesa/ESD: nzira dzekuyedza uye mhedzisiro. Electrical Overstress/Electrostatic Discharge Symposium Proceedings. 1998 (Cat. Nhamba 98TH8347).

Stowers, I. (1999). Tsanangudzo dzekuchenesa maziso uye kusimbiswa kwekuchenesa. Magwaro eSPIE.

Chubb, J. (2008). Zvidzidzo zveTribocharging pazvipfeko zvemukamuri rakachena zvinogarwa. Journal of Electrostatics, 66, 531-537.

Hu, S.-C., & Shiue, A. (2016). Kusimbiswa uye kushandiswa kwechinhu chinoshandiswa pabasa remumba chinoshandiswa mumakamuri ekuchenesa. Zvivako neNzvimbo.

Nguva yekutumira: Kubvumbi-24-2024