Mundima yema laser ane simba guru, ma laser bars zvinhu zvakakosha zvikuru. Haangoshandi sezvikamu zvesimba chete, asi anosanganisirawo kunyatsorongeka uye kubatanidzwa kweinjiniya yemazuva ano ye optoelectronic.—zvichivapa zita remadunhurirwa rekuti: "injini" yemasisitimu elaser. Asi chimiro chelaser bar chii chaizvo, uye chinoburitsa sei makumi kana kunyange mazana ema watts emushonga kubva kumamirimita mashoma chete muhukuru? Chinyorwa chino chinoongorora magadzirirwo emukati uye zvakavanzika zveinjiniya zviri mukati melaser bar.

1. Chii chinonzi Laser Bar?

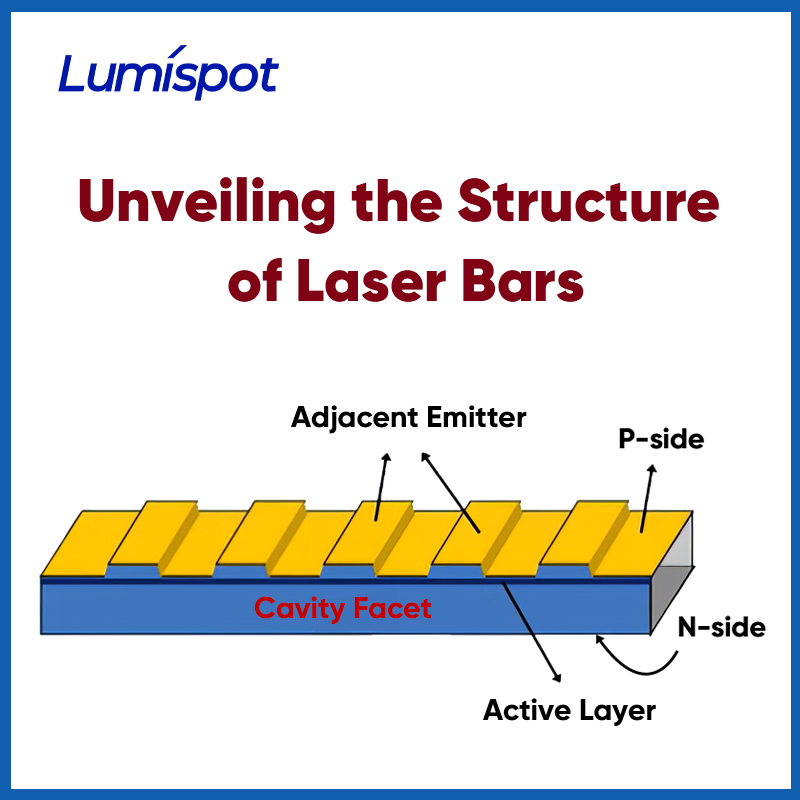

Bhawa reLaser mudziyo unoburitsa simba guru une machipisi akawanda eLaser Diode akarongwa padivi pane imwe substrate. Kunyange hazvo mashandiro aro akafanana neeLaser imwe chete yesemiconductor, bhawa reLaser rinoshandisa multi-emitter layout kuti riwane simba repamusoro rekuona uye chimiro chakabatana.

Mabhawa eLaser anoshandiswa zvakanyanya muzvikamu zveindasitiri, zvekurapa, zvesainzi, uye zvekudzivirira, kungave semanyuko elaser yakananga kana semanyuko epombi efiber lasers uye solid-state lasers.

2. Kuumbwa kweLaser Bar

Maumbirwo emukati mebhawa relaser anonyatso sarudza mashandiro aro. Rinonyanya kusanganisira zvikamu zvikuru zvinotevera:

①Emitters Array

Mitsetse yeLaser inowanzo kuve nemaemitter gumi kusvika zana (laser cavities) akarongwa padivi nepadivi. Emitter imwe neimwe inosvika makumi mashanu–150μine upamhi hwem uye inoshanda senzvimbo yakazvimirira yekuwana, ine PN junction, resonant cavity, uye waveguide structure yekugadzira nekuburitsa chiedza chelaser. Kunyange zvazvo maemitter ese aine substrate imwe chete, anowanzo fambiswa nemagetsi munzvimbo dzakafanana kana kuti nenzvimbo.

②Maumbirwo eSemiconductor Layer

Pakati pebhawa relaser pane murwi wezvikamu zve semiconductor, zvinosanganisira:

- P-type uye N-type epitaxial layers (zvinoumba PN junction)

- Chimiro chinoshanda (semuenzaniso, chimiro chetsime re quantum), chinoburitsa kuburitswa kwemhepo kunosimudzirwa

- Waveguide layer, ichivimbisa kudzora nzira munzira dzakatarisana nedzakatwasuka

- Bragg reflectors kana HR/AR coatings, izvo zvinowedzera kubuda kwelaser zvakananga

③Maitiro ekugadzirisa Substrate neThermal

Ma emitter anorimwa pa monolithic semiconductor substrate (inowanzova GaAs). Kuti kupisa kuparadzike zvakanaka, laser bar inosungirirwa pazvigadziko zve high-conductivity zvakaita se copper, W-Cu alloy, kana CVD diamond, uye inosanganiswa nema heat sinks uye active cooling systems.

④Pamusoro peKubuda Kwemhepo uye Sisitimu yeKuputika Kwemhepo

Nekuda kwemakona makuru ekusiyana kwematanda anoburitswa, mabara elaser anowanzo kuve ne micro-lens arrays (FAC/SAC) yekuumba collimation uye kuveza beam. Kune mamwe maapplication, mamwe ma optics—zvakaita semalenzi e cylindrical kana ma prism—zvinoshandiswa kudzora kusiyana kwenzvimbo dziri kure uye mhando yemwaranzi.

3. Zvinhu Zvikuru Zvinoita Kuti Magadzirirwo Ezvinhu Ashande

Maumbirwo ebhawa relaser ane basa rakakosha pakuona kugadzikana kwaro, kushanda kwaro, uye hupenyu hwaro. Zvinhu zvakakosha zvinosanganisira:

①Dhizaini yeKutarisira Kupisa

Mabhawa eLaser ane simba rakawanda uye kupisa kwakasimba. Kusapisa kwakaderera kwakakosha, kunowanikwa kuburikidza neAuSn soldering kana indium bonding, pamwe chete nekutonhodza microchannel kuti kupisa kuparare zvakaenzana.

②Kuumba uye Kurongeka kweMatanda

Maemitter akawanda anowanzo sangana nematambudziko ekubatana zvakanaka uye kusarongeka zvakanaka kwewavefront. Kugadzirwa kwemalenzi ekunyatsorongeka uye kurongeka kwakakosha pakuvandudza kunaka kwemwaranzi wefar-field.

③Kudzora Kushushikana uye Kuvimbika

Kusawirirana kwezvinhu mukuwedzera kwemafuta kunogona kukonzera kukweshana kana kuti kutsemuka kwechinhu. Kurongedza kunofanirwa kugadzirwa kuti kugovane kushushikana kwemuchina zvakaenzana uye kugone kutsungirira kupisa pasina kuora.

4. Mafambiro Emangwana Mukugadzira Laser Bar

Sezvo kudiwa kwesimba rakawanda, saizi diki, uye kuvimbika kuri kuwedzera, zvimiro zve laser bar zviri kuramba zvichichinja. Nzira huru dzekuvandudza dzinosanganisira:

①Kuwedzera kweWavelength: Kusvika pa1.5μm uye mid-infrared bands

②Kugadzira zvinhu zvishoma: Kugonesa kushandiswa mumidziyo midiki uye mamodule akabatanidzwa zvakanyanya

③Kurongedza Kwakangwara: Kubatanidza masensa ekupisa uye masisitimu emhinduro dzemamiriro ezvinhu

④Kuisa Zvinhu Zvakanyanya Kuwanda: Magadzirirwo ezvikamu kuti awane kilowatt-level output muchikamu chidiki chetsoka

5. Mhedziso

Sezvo"moyo""yemasisitimu e-laser ane simba guru, dhizaini yemabara e-laser inokanganisa zvakananga mashandiro emagetsi, emagetsi, uye ekupisa esisitimu yese. Kubatanidza akawanda ema-emitter muchimiro chakafara mamirimita chete hakungoratidzi chete matekiniki epamusoro ekugadzira, asiwo kunomiririra huwandu hwepamusoro hwekubatanidzwa nhasi.'indasitiri ye photonics.

Tichitarisa mberi, sezvo kudiwa kwemasosi elaser anoshanda uye akavimbika kuri kuramba kuchiwedzera, hunyanzvi muchimiro chelaser bar hucharamba huri chinhu chikuru mukusimudzira indasitiri yelaser kusvika padanho idzva.

Kana iwe'Tiri kutsvaga rubatsiro rwenyanzvi mukupakira mabara e laser, manejimendi yekupisa, kana kusarudza zvigadzirwa, inzwa wakasununguka kutibata. Isu.'tiri pano kuti tipe mhinduro dzakagadzirirwa iwe kuti dzienderane nezvinodiwa zvako zvekushandisa.

Nguva yekutumira: Chikunguru-02-2025