Mukushandiswa kwakadai sema laser ane simba guru, zvishandiso zvemagetsi zvine simba, uye masisitimu ekutaurirana, kuwedzera kwekushandiswa kwesimba uye huwandu hwekubatanidza kwakaita kuti manejimendi yekupisa ive chinhu chakakosha chinokanganisa mashandiro echigadzirwa, hupenyu hwese, uye kuvimbika. Pamwe chete nekutonhodza kwe micro-channel,kutonhora kwemacro-channelyave nzira inoshanda yekutonhodza mvura. Chimiro chayo chiri nyore, mutengo wakaderera, uye kugadzirisa kuri nyore zvinoita kuti ive yakakodzera zvakanyanya kune akawanda maindasitiri.

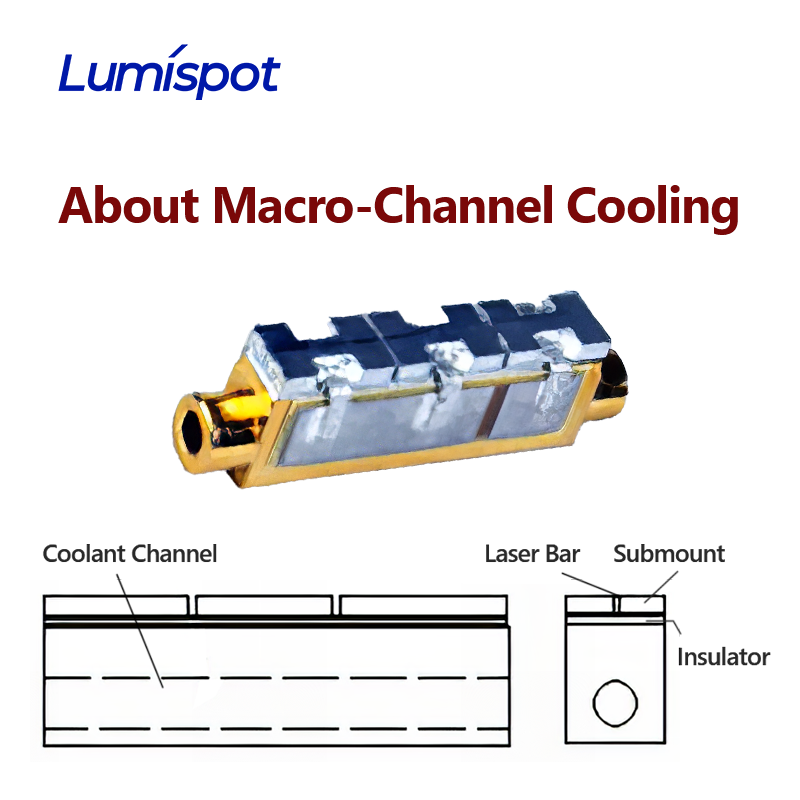

1. Chii Chinonzi Macro-Channel Cooling?

Kutonhodza kweMacro-channel kunosanganisira kushandiswa kwenzira dzakakura dzinotonhodza (dzinowanzova mu millimeter range) dzakavakirwa muma coolant plates kana modules. Nzira idzi dzinotungamira coolant fluids—dzinowanzova mvura isina ionized, glycol-based solutions, kana zvimwe zvinotonhodza zveindasitiri—kuburikidza nesystem iyi kubvisa kupisa kunobva panguva yekushanda kwemudziyo. Kana zvabatanidzwa ne water-cooling loop, iyi setup inogonesa kudzora kupisa kunoenderera mberi uye kunoshanda.

2. Macro-Channel vs. Micro-Channel: Misiyano mikuru

| Chinhu | Kutonhodza kweMacro-Channel | Kutonhodza kweMicro-Channel |

| Saizi yeChiteshi | Chikero che mirimita (1mm kusvika akati wandei mm) | Chikero che micrometer (makumi kusvika mazana e μm) |

| Kuoma Kwekugadzira | Zvakaderera zvishoma | Inoda michina yakanyatsogadzirwa |

| Kuramba Kuyerera | Mvura inoyerera zviri nyore, yakaderera | Yakakwira, inoda kumanikidzwa kwakanyanya kwepombi |

| Kushanda Nesimba Pakuchinjana Kupisa | Pakati nepakati, yakakodzera kupisa kwepakati | Yakakwirira, yakakodzera kupisa kwakanyanya |

| Mutengo | Zasi | Yepamusoro |

| Kushandiswa Kwakajairika | Masisitimu ekupisa anosvika pakati nepakati kusvika pasi, akavimbika zvakanyanya | Kuwanda kwesimba guru, masosi ekupisa ari munzvimbo imwe chete |

3. Mabhenefiti eMacro-Channel Cooling

Kunyangwe kushanda kwayo kwekupisa kwakaderera pane mhinduro dze micro-channel, kutonhora kwe macro-channel kune mabhenefiti akati wandei anozivikanwa:

①Kuvimbika kwakanyanya:

Nzira dzakakura hadziwanzovharika, zvichipa kugadzikana kwakanaka kwenguva refu—zvakanakira kushanda nguva dzose mumaindasitiri.

②Mari shoma yekugadzira:

Chimiro chakareruka uye sarudzo dzakasiyana-siyana dzekugadzira zvinoita kuti ive yakakodzera kugadzirwa kwevanhu vakawanda.

③Kugadzirisa kuri nyore:

Nguva refu yekuchenesa, mari shoma yekugadzirisa, uye zvinodiwa zvishoma zvekuchenesa zvinhu zvinotonhodza.

④Kukwanisa kutonhora kwakakwana:

Kumidziyo ine kupisa kuri pakati nepakati, kutonhora kwemacro-channel kunonyatsochengetedza tembiricha yekushanda kwayo uye kunoita kuti hupenyu hwemuchina huwedzere.

4. Maitiro Ekushandisa

Kutonhodza kweMacro-channel kunoshandiswa zvakanyanya munzvimbo dzinotevera:

①Mamodule eLaser:

Kunyanya kune ma-laser ane simba repakati kusvika pasi kana kuti CW-mode, macro-channel systems anogona kubata zviri nyore mutoro wekupisa.

②Mamodule emagetsi emagetsi:

Zvakadai sema rectifiers, ma converters eDC-DC, uye ma IGBT modules.

③Ma amplifiers emagetsi mukutaurirana uye masisitimu eradar:

Yakanakira nzvimbo dzakaoma dzinoda kushanda kwenguva refu uye kwakasimba.

④Masisitimu ekutonhodza mumidziyo yekurapa neyemaindasitiri:

Kusanganisira michina yekurapa nelaser ye semiconductor, michina yekuisa chiratidzo nelaser, nezvimwewo.

5. Zvinhu Zvikuru Zvekufunga Nezvekugadzira Macro-Channel Cooling

Mhinduro yekutonhodza ye macro-channel inobudirira inoda kutariswa nezvinhu zvinotevera:

①Kurongeka kwechiteshi:

Inofanira kugadziriswa zvichienderana nekugoverwa kwekupisa kwemudziyo kuti itonhore zvakaenzana.

②Sarudzo yezvinhu:

Mhangura, simbi isina ngura, kana aruminiyamu alloys dzinowanzo shandiswa nekuda kwekukwira kwekupisa uye kuramba ngura.

③Mwero wekuyerera uye kuenderana kwepombi:

Kugadzirwa kwakanaka kwekumhanya kwemvura uye kuyerera kwechinhu chinotonhodza kunoita kuti kuchinjana kwekupisa kushande zvakanaka uye kugadzikana kwehurongwa.

④Nzvimbo dzakajairwa:

Inogonesa kubatanidzwa zviri nyore mumidziyo yevatengi kana mamodule.

6. Mhedziso

Kutonhodza macro-channel kunoramba kuchiita basa rakakosha mumaindasitiri nekuda kwekureruka kwayo, kuvimbika, uye nyore kugadzirisa. Imhinduro inodhura uye yakavimbika, kunyanya mumasisitimu ane huwandu hwekupisa huri pakati nepakati kusvika pasi. Sezvo dhizaini yemidziyo ichichinja, mhinduro dzemacro-channel dziri kufambira mberiwo kusvika pakubatanidzwa kwepamusoro uye kuvandudzwa kwekuchinja.

7. Nezvedu

Lumispotinopa hunyanzvi hwakakura mukugadzirisa kwemagetsi emagetsi madiki nemadiki. Isu tinopa mamodule ekutonhodza akagadzirirwa ma lasers, zvishandiso zve optoelectronic, magetsi emagetsi, nezvimwewo. Chinangwa chedu chinopfuura kushanda kwemagetsi - tinokoshesa kubatanidzwa kwemasisitimu uye kuvimbika kwenguva refu, tichivavarira kupa masisitimu ekutonhodza anoshanda zvakanyanya uye asingadhuri.

Sunungukai kutibata kuti mudzidze zvakawanda nezve macro-channel uye micro-channel cooling solutions dzakagadzirirwa zvaunoda pakushandisa!

Nguva yekutumira: Chikumi-17-2025