Nyorera kuSocial Media Yedu Kuti Uwane Chiziviso Chinokurumidza

Nhanganyaya yeLaser Processing muManufacturing

Tekinoroji yekugadzirisa laser yave nekukura nekukurumidza uye inoshandiswa zvakanyanya muminda yakasiyana-siyana, senge mudenga, mota, zvemagetsi, nezvimwewo. Inoita basa guru mukuvandudza mhando yechigadzirwa, kubereka kwevashandi, uye otomatiki, ukuwo ichideredza kusvibiswa uye kushandiswa kwezvinhu (Gong, 2012).

Kugadziriswa kweLaser muZvinhu zveSimbi neZvisiri zveSimbi

Kushandiswa kukuru kwelaser processing mumakore gumi apfuura kwave kuri muzvinhu zvesimbi, zvinosanganisira kucheka, kusanganisa, uye kufukidza. Zvisinei, munda uyu uri kuwedzera kuita zvinhu zvisiri zvesimbi zvakaita semachira, magirazi, mapurasitiki, mapolymer, uye zviumbwa zvesimbi. Chimwe nechimwe chezvinhu izvi chinovhura mikana mumaindasitiri akasiyana-siyana, kunyangwe vatove nematekiniki ekugadzirisa (Yumoto et al., 2017).

Matambudziko uye Zvitsva muKugadzirwa kweGirazi neLaser

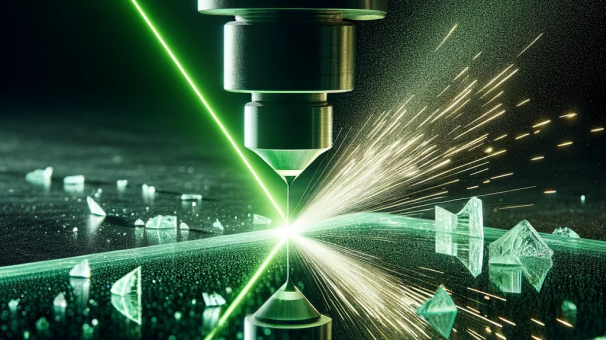

Girazi, rine mashandisirwo aro akawanda mumaindasitiri akadai semotokari, kuvaka, uye zvemagetsi, rinomiririra nzvimbo yakakosha yekugadzirisa nelaser. Nzira dzekucheka magirazi dzechinyakare, dzinosanganisira maturusi akaomarara kana madhaimani, dzinogumira pakushanda zvishoma uye mipendero yakaoma. Kusiyana neizvi, kucheka nelaser kunopa imwe nzira inoshanda uye yakanyatsojeka. Izvi zvinonyanya kuoneka mumaindasitiri akaita sekugadzira mafoni, uko kucheka nelaser kunoshandiswa pamakamera lens cover uye magirazi makuru ekuratidza (Ding et al., 2019).

Kugadziriswa kweLaser kweMarudzi eGirazi Akakosha Kwazvo

Magirazi akasiyana-siyana, akadai segirazi re optical, girazi re quartz, uye girazi re sapphire, ane matambudziko akasiyana nekuda kwekusasimba kwawo. Zvisinei, matekiniki epamusoro e laser akadai se femtosecond laser etching akagonesa kugadziriswa kwezvinhu izvi nemazvo (Sun & Flores, 2010).

Simba reWavelength paMaitiro eLaser Technology

Kureba kwewaya yelaser kunokanganisa zvakanyanya maitiro acho, kunyanya pazvinhu zvakaita sesimbi yekuvaka. Malaser anoburitsa munzvimbo dzeinfrared dzinoonekwa, dziri pedyo nedziri kure akaongororwa kuti aone simba rawo guru rekunyungudutsa nekupwanya (Lazov, Angelov, & Teirumnieks, 2019).

Mashandisirwo Akasiyana-siyana Akavakirwa paWavelengths

Kusarudzwa kwewavelength yelaser hakusi kwekusarudzika asi kunoenderana zvakanyanya nechimiro chechinhu chacho uye mhedzisiro inodiwa. Semuenzaniso, maUV lasers (ane wavelength pfupi) akanakira kunyora nemazvo uye micromachining, sezvo achigona kugadzira zvinhu zvakapfava. Izvi zvinoita kuti zvive zvakanaka kumaindasitiri e semiconductor nema microelectronics. Kusiyana neizvi, ma infrared lasers anoshanda zvakanyanya pakugadzirisa zvinhu zvakakora nekuda kwekugona kwawo kupinda mukati zvakanyanya, zvichiita kuti akwanise kushandiswa mumaindasitiri akawanda. (Majumdar & Manna, 2013). Saizvozvowo, ma green lasers, anowanzo shanda pawavelength ye532 nm, anowana nzvimbo yawo mukushandiswa kunoda kunyatsojeka kwakanyanya uye kupisa kushoma. Anonyanya kushanda mu microelectronics pamabasa akadai se circuit patterning, mukushandiswa kwekurapa kwemaitiro akadai se photocoagulation, uye muchikamu chesimba rinodzokororwa pakugadzira solar cell. Wavelength yakasiyana yeGreen lasers inoitawo kuti ive yakakodzera kumaka nekunyora zvinhu zvakasiyana-siyana, kusanganisira mapurasitiki nesimbi, uko kusiyanisa kwakanyanya uye kukuvara kushoma kwepamusoro kunodiwa. Kuchinjika uku kwe green lasers kunoratidza kukosha kwekusarudza wavelength mu tekinoroji ye laser, zvichiita kuti pave nemigumisiro yakanaka kune zvimwe zvinhu nemashandisirwo.

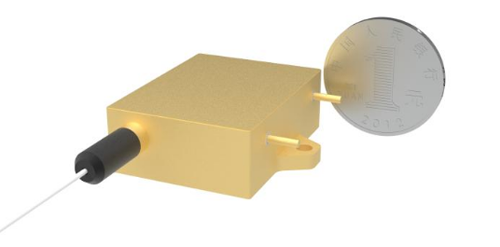

Iyo525nm girini laserimhando chaiyo yetekinoroji yelaser inozivikanwa nekubuda kwayo kwechiedza chegirini pahurefu hwe525 nanometers. Malaser egirini pahurefu uhwu anowana mashandisirwo mu retina photocoagulation, uko simba rawo guru uye kunyatsojeka zvinobatsira. Anogonawo kubatsira mukugadzirisa zvinhu, kunyanya munzvimbo dzinoda kugadziriswa kwakanyatsojeka uye kushoma kwekupisa..Kugadzirwa kwemadiode egirini elaser pa c-plane GaN substrate kuenda kumarefu ewavelength pa524–532 nm kunoratidza kufambira mberi kukuru mu tekinoroji yelaser. Kuvandudzwa uku kwakakosha kune mashandisirwo anoda hunhu hwakasiyana hwewavelength.

Mafungu Anoenderera Mberi uye Matsime eLaser Akavharirwa

Mafungu anoenderera mberi (CW) uye matsime elaser ane quasi-CW akaumbwa pamhando dzakasiyana dzemafungu akadai se near-infrared (NIR) pa1064 nm, green pa532 nm, uye ultraviolet (UV) pa355 nm zvinoonekwa pamasero ezuva anobvisa madope elaser. Mafungu akasiyana ane zvazvinoreva pakugadzirisa uye kushanda zvakanaka kwekugadzira (Patel et al., 2011).

MaLaser eExcimer eZvinhu zveWide Band Gap

Malaser eExcimer, anoshanda neUV wavelength, akakodzera kugadzirisa zvinhu zvakaita segirazi necarbon fiber-reinforced polymer (CFRP), zvichipa kunyatsojeka uye kupisa kushoma (Kobayashi et al., 2017).

Nd:YAG Lasers dzeMashandisirwo Emaindasitiri

MaLaser eNd:YAG, ane kugona kuchinjika pakugadzirisa urefu hwewavelength, anoshandiswa mumhando dzakasiyana-siyana. Kugona kwawo kushanda pa1064 nm ne532 nm kunobvumira kuchinjika pakugadzirisa zvinhu zvakasiyana. Semuenzaniso, urefu hwewavelength hwe1064 nm hwakanakira kuveza zvakadzika pasimbi, nepo urefu hwewavelength hwe532 nm huchipa kuveza kwepamusoro-soro pamapurasitiki nesimbi dzakaputirwa. (Moon et al., 1999).

→Zvigadzirwa Zvakabatana:Laser yakasimba inopombwa ne CW Diode ine 1064nm wavelength

Kukwesha kweLaser yeFiber ine Simba Repamusoro

MaLaser ane marefu ehupamhi ari pedyo ne1000 nm, ane mhando yakanaka yemwenje uye simba rakawanda, anoshandiswa mukusanganisa simbi ne keyhole laser. MaLaser aya anonyungudutsa nekunyungudutsa zvinhu zvinobudirira, zvichigadzira ma weld emhando yepamusoro (Salminen, Piili, & Purtonen, 2010).

Kubatanidzwa kweLaser Processing nedzimwe Tekinoroji

Kubatanidzwa kwekugadzirwa kwelaser nedzimwe nzira dzekugadzira, dzakadai secladding nekugaya, kwakaita kuti pave nemaitiro ekugadzira anoshanda uye akasiyana-siyana. Kubatanidzwa uku kunobatsira zvikuru mumaindasitiri akadai sekugadzira maturusi nemadhiraivha uye kugadzirisa injini (Nowotny et al., 2010).

Kugadziriswa kweLaser muMinda Inobudirira

Kushandiswa kwetekinoroji yelaser kunosvika kuminda iri kubuda senge maindasitiri e semiconductor, display, uye thin film, zvichipa kugona kutsva nekuvandudza hunhu hwezvinhu, kunyatsogadzirwa kwechigadzirwa, uye mashandiro emudziyo (Hwang et al., 2022).

Mafambiro Emangwana Mukugadzirisa NeLaser

Kufambira mberi mune ramangwana mukugadzirwa kwetekinoroji yelaser kunotarisa pahunyanzvi hutsva hwekugadzira, kuvandudza kunaka kwezvigadzirwa, hunyanzvi hwekugadzira zvinhu zvakawanda zvakasanganiswa uye kuwedzera mabhenefiti ehupfumi nemaitiro. Izvi zvinosanganisira kugadzirwa nekukurumidza kwezvivakwa zvine maburi akadzora, welding yehybrid, uye kucheka machira esimbi nelaser profile (Kukreja et al., 2013).

Tekinoroji yekugadzirisa laser, ine mashandisirwo ayo akasiyana-siyana uye hunyanzvi hunoramba huripo, iri kuumba ramangwana rekugadzira nekugadzira zvinhu. Kuchinja-chinja kwayo uye kunyatsoita kwayo zvinoita kuti ive chishandiso chakakosha mumaindasitiri akasiyana-siyana, zvichipfuura miganhu yenzira dzechinyakare dzekugadzira.

Lazov, L., Angelov, N., & Teirumnieks, E. (2019). NZIRA YEKUTANGA YEKUFUNGIDZIRA KWESIMBA RAKAKOSHA MUMATANHO ECHINOSHANDISA LASER.ZVAKASINGANWI. MATEKINOLOJI. ZVINHU. ZVINOITIKA MUMUSONHO WESAINZI NEMASHANDISIRO ENYIKA YOSE. Chinongedzo

Patel, R., Wenham, S., Tjahjono, B., Hallam, B., Sugianto, A., & Bovatsek, J. (2011). Kugadzirwa Kwekukurumidza KwemaLaser Doping Selective Emitter Solar Cells Achishandisa 532nm Continuous Wave (CW) uye Modelocked Quasi-CW Laser Sources.Chinongedzo

Kobayashi, M., Kakizaki, K., Oizumi, H., Mimura, T., Fujimoto, J., & Mizoguchi, H. (2017). DUV yakakwirira simba lasers kugadzirisa girazi uye CFRP.Chinongedzo

Moon, H., Yi, J., Rhee, Y., Cha, B., Lee, J., & Kim, K.-S. (1999). Kuwanda kwemukati memugero kunowedzera kaviri kubva kune laser yeNd:YAG inoyerera ichiburitsa chiedza uchishandisa kristaro yeKTP.Chinongedzo

Salminen, A., Piili, H., & Purtonen, T. (2010). Hunhu hwepamusoro simba fiber laser welding.Zvakaitika kuInstitution of Mechanical Engineers, Chikamu C: Journal of Mechanical Engineering Science, 224, 1019-1029.Chinongedzo

Majumdar, J., & Manna, I. (2013). Nhanganyaya yekugadzirwa kwezvinhu neLaser.Chinongedzo

Gong, S. (2012). Kuferefeta uye mashandisirwo etekinoroji yepamusoro yekugadzira laser.Chinongedzo

Yumoto, J., Torizuka, K., & Kuroda, R. (2017). Kugadzirwa kweMubhedha weKuedza weLaser-Manufacturing uye Database yeLaser-Material Processing.Ongororo yeLaser Engineering, 45, 565-570.Chinongedzo

Ding, Y., Xue, Y., Pang, J., Yang, L.-j., & Hong, M. (2019). Kufambira mberi mu-situ yekutarisa tekinoroji yelaser processing.SCIENTIA SINICA Physica, Mechanica & Astronomica. Chinongedzo

Sun, H., & Flores, K. (2010). Kuongororwa kweMicrostructural kweGirazi resimbi rakagadziriswa neLaser-Based Zr-Based Bulk Metallic.Kutengeserana Kwesimbi Nezvinhu A. Chinongedzo

Nowotny, S., Muenster, R., Schharek, S., & Beyer, E. (2010). Sero re laser rakabatanidzwa rekubatanidza laser nekugaya.Kugadzira otomatiki kweAssembly, 30(1), 36-38.Chinongedzo

Kukreja, LM, Kaul, R., Paul, C., Ganesh, P., & Rao, BT (2013). Matekiniki Ekugadzira Zvinhu zveLaser Achiri Kubudirira Ekushandisa Maindasitiri Emangwana.Chinongedzo

Hwang, E., Choi, J., & Hong, S. (2022). Maitiro matsva ekubvisa tsvina achishandisa laser ekugadzira zvinhu nemazvo uye zvinopa goho rakakura.Nanoscale. Chinongedzo

Nguva yekutumira: Ndira-18-2024