Sezvo tekinoroji yelaser ine simba guru ichiramba ichifambira mberi nekukurumidza, maLaser Diode Bars (LDBs) ave kushandiswa zvakanyanya mukugadzira maindasitiri, kuvhiya kwezvokurapa, LiDAR, uye kutsvagisa kwesainzi nekuda kwesimba rawo rakawanda uye kupenya kwakanyanya. Zvisinei, nekuwedzera kwekubatanidzwa uye kushanda kwemagetsi elaser chips, matambudziko ekutonga kupisa ari kuwedzera - zvichikanganisa zvakananga kugadzikana kwekushanda uye hupenyu hwelaser.

Pakati penzira dzakasiyana-siyana dzekutarisira kupisa, Contact Conducting Cooling inoonekwa seimwe yenzira dzakakosha uye dzakajairika mukupakira kwebhawa re laser diode, nekuda kwechimiro chayo chiri nyore uye kufambisa kupisa kwakanyanya. Chinyorwa chino chinoongorora misimboti, pfungwa huru dzekugadzira, kusarudzwa kwezvinhu, uye mafambiro eramangwana eiyi "nzira yakadzikama" yekudzora kupisa.

1. Nheyo dzeKutonhodza Kufambisa Kubata

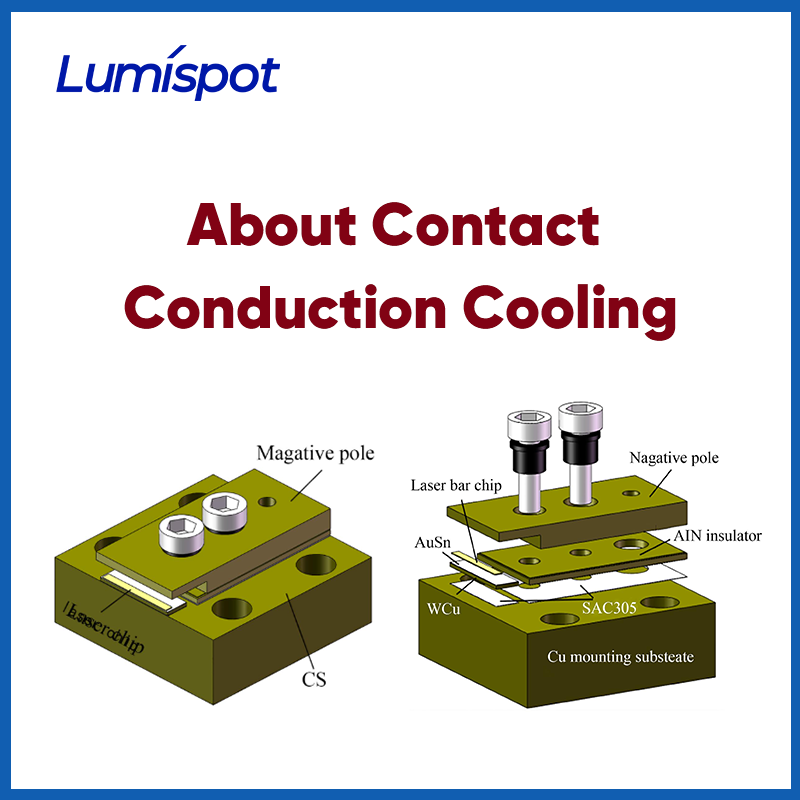

Sezvinoratidzwa nezita racho, kutonhora kwe contact conduction kunoshanda nekugadzira kubatana kwakananga pakati pe laser chip ne heat sink, zvichiita kuti kupisa kupfuure zvakanaka kuburikidza nezvinhu zvinopisa zvakanyanya uye kupararira nekukurumidza kunzvimbo yekunze.

①The HidyaPath:

Mubhawa re laser diode rakajairika, nzira yekupisa ndeiyi inotevera:

Chip → Solder Layer → Submount (semuenzaniso, copper kana ceramic) → TEC (Thermoelectric Cooler) kana Heat Sink → Ambient Environment

②Zvimiro:

Nzira iyi yekutonhodza ine zvinhu zvinotevera:

Kuyerera kwekupisa kwakasimba uye nzira pfupi yekupisa, zvinoderedza tembiricha yejunction zvinobudirira; Dhizaini diki, yakakodzera kurongedza kadiki; Kufambisa kwemhepo kusingashande, kusingade zvidzitiro zvakaoma zvekutonhodza.

2. Zvinhu Zvikuru Zvinofanira Kufungwa Nezvekugadzira Mashandiro Ekupisa

Kuti zvive nechokwadi chekuti contact conduction inotonhorera zvakanaka, zvinhu zvinotevera zvinofanirwa kutariswa nokungwarira panguva yekugadzira mudziyo:

① Kuramba Kupisa paSolder Interface

Kufambiswa kwemafuta emuchina we solder layer kunoita basa rakakosha mukudzivirira kupisa. Simbi dzine simba re conductivity dzakadai seAuSn alloy kana pure indium dzinofanira kushandiswa, uye ukobvu uye kufanana kwe solder layer zvinofanirwa kudzorwa kuderedza zvipingamupinyi zvekupisa.

② Sarudzo Yezvinhu Zviri Pasi Pevhu

Zvinhu zvakajairika zve submount zvinosanganisira:

Mhangura (Cu): Inofambisa kupisa kwakanyanya, isingadhuri;

Tungsten Copper (WCu)/Molybdenum Copper (MoCu): CTE inoenderana nemachipisi zviri nani, zvichipa simba uye conductivity;

Aluminum Nitride (AlN): Inodziisa magetsi zvakanaka, yakakodzera kushandiswa nemagetsi ane simba guru.

③ Hunhu hweKubata Pamusoro

Kuomarara kwepamusoro, kusatsetseka, uye kunyorova kunokanganisa zvakananga mashandiro ekutamisa kupisa. Kupukuta uye kupenda kwegoridhe zvinowanzo shandiswa kuvandudza mashandiro ekupisa.

④ Kuderedza Nzira yekupisa

Dhizaini yechivako inofanira kupfupisa nzira yekupisa iri pakati pechip nechitofu. Dzivisa kuisa zvinhu zvepakati zvisina basa kuti uvandudze kushanda zvakanaka kwekupisa.

3. Nzira dzekuvandudza ramangwana

Nekuda kwekuwedzera kuri kuita simba shoma uye kuwanda kwesimba, tekinoroji yekutonhodza contact ...

① MaTIM ane machira akawanda

Kusanganisa simbi inofambisa kupisa ne flexible buffering kuderedza resistance ye interface uye kuvandudza thermal cycling kugara kwenguva refu.

② Kurongedza Sinki Yekupisa Yakabatanidzwa

Kugadzira ma submount nema heat sinks sechivakwa chimwe chete chakabatanidzwa kuderedza ma contact interfaces uye kuwedzera kushanda zvakanaka kwe system-level heat transfer.

③ Kugadzirisa Magadzirirwo Ezvinhu Zvakafanana Nemabhiyoni

Kushandisa nzvimbo dzakagadzirwa ne microstructure dzinotevedzera nzira dzechisikigo dzekuparadza kupisa—dzakadai se “kuburitsa kwakaita semuti” kana “mapatani akafanana nesikaru”—kuti kuwedzere kushanda kwekupisa.

④ Kudzora Kupisa Kwakangwara

Kusanganisira masensa ekupisa uye simba rinochinja-chinja rekutonga kupisa, zvichiwedzera hupenyu hwekushanda kwemudziyo.

4. Mhedziso

Kune ma laser diode bars ane simba guru, kutonga kupisa hakusi dambudziko rehunyanzvi chete - ihwaro hwakakosha hwekuvimbika. Kutonhodza kwe contact conduction, nehunhu hwayo hunoshanda, hwakakura, uye husingadhuri, kuchiri imwe yemhinduro huru dzekuparadza kupisa nhasi.

5. Nezvedu

KuLumispot, tinounza hunyanzvi hwakadzama mukurongedza madhiode elaser, kuongorora manejimendi ekupisa, uye kusarudza zvinhu. Chinangwa chedu ndechekupa mhinduro dzelaser dzinoshanda zvakanyanya uye dzinogara kwenguva refu dzakagadzirirwa zvaunoda. Kana uchida kudzidza zvakawanda, tinokugamuchira neushamwari kuti utaure nechikwata chedu.

Nguva yekutumira: Chikumi-23-2025